titanium 3d printer

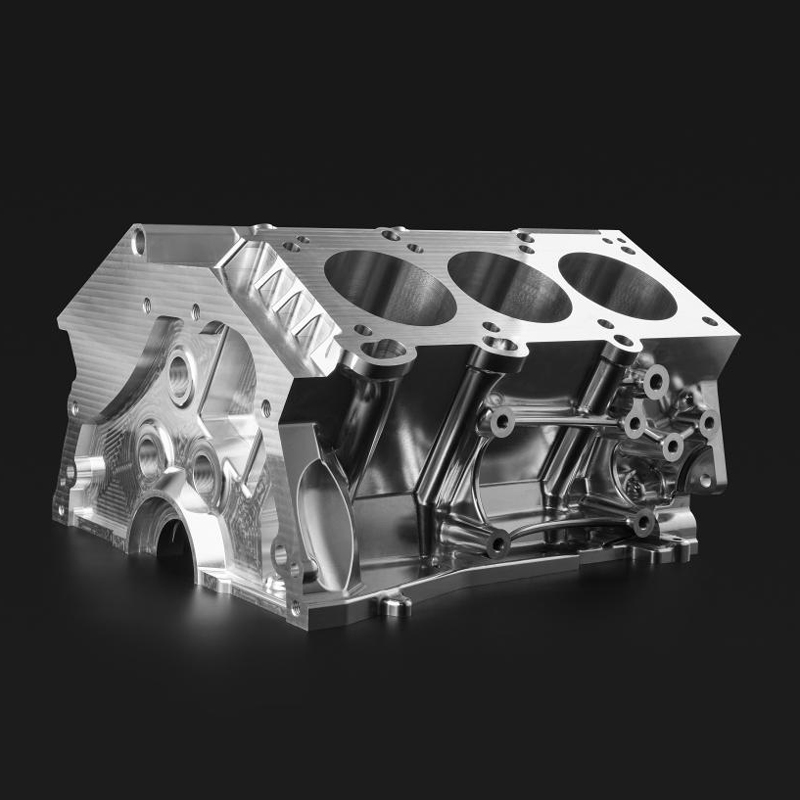

When discussing titanium 3D printers, it's essential to delve into the technology's capabilities, applications, and the significance it holds in today's manufacturing landscape. Titanium, a lightweight yet incredibly strong metal, has long been a sought-after material for various industries, from aerospace to medical implants. However, its high melting point and reactivity with other elements have made traditional manufacturing methods challenging and costly. This is where titanium 3D printing comes into play, revolutionizing the way we produce titanium components. Titanium 3D printers utilize advanced additive manufacturing techniques to build complex titanium structures layer by layer. These printers are capable of processing titanium powder or wire, fusing it together under extreme temperatures to create solid, precision-engineered parts. The process, known as powder bed fusion or directed energy deposition, allows for the creation of intricate geometries that would be difficult or impossible to achieve with traditional machining methods. The benefits of titanium 3D printing are numerous. Firstly, it significantly reduces material waste, as only the necessary amount of titanium is used to create the desired part. This not only saves on costs but also reduces the environmental impact of manufacturing. Secondly, titanium 3D printing enables the production of lightweight yet highly durable components, ideal for applications where weight reduction is crucial, such as in aerospace and automotive industries. The aerospace industry, particularly, has seen a significant shift towards titanium 3D printing. Traditional manufacturing methods for titanium parts, such as forging and casting, are notoriously time-consuming and expensive. Titanium 3D printers, on the other hand, can quickly produce complex parts with high accuracy, enabling faster turnaround times and lower costs. This has led to a surge in the adoption of 3D-printed titanium components in aircraft and spacecraft, from engine parts to structural components.