The Advantages of 3D Printing for Mass Production

3D printing has revolutionized the way we manufacture products by allowing for mass production in a more efficient and cost-effective manner. Traditional manufacturing methods often involve lengthy processes, high costs, and limitations on design creativity. However, 3D printing offers a solution to these problems by using computer-aided design technology to create three-dimensional objects with various materials.

This article explores the advantages of 3D printing for mass production, including increased speed, lower costs, improved customization, and reduced waste. In this article, we will also discuss how 3D printing is changing the manufacturing landscape and its potential impact on various industries such as automotive, aerospace, and consumer goods. With its ability to produce complex designs quickly and economically, 3D printing has become a game-changer in the world of mass production.

What is 3D Printing?

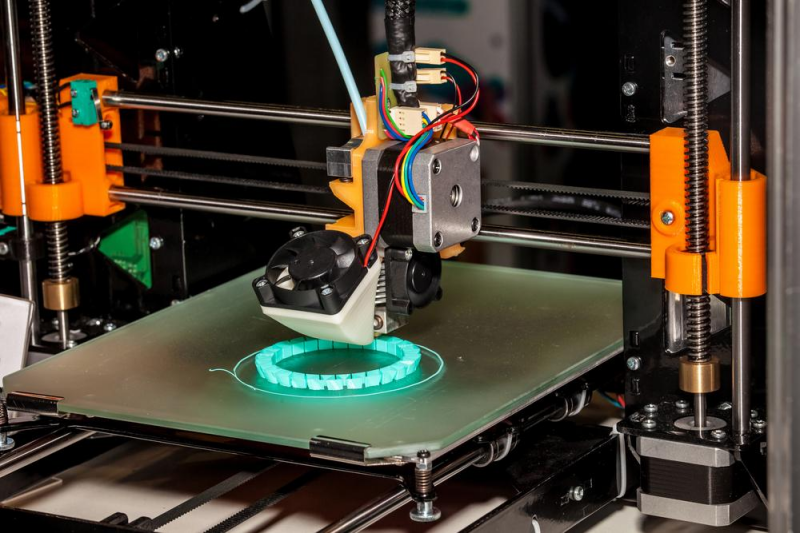

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by laying down layers of material in a predetermined pattern. This technology was first developed in the 1980s but has gained popularity and advancement in recent years due to its potential for mass production.

The process starts with a digital design created through computer-aided design (CAD) software or obtained from 3D scanning. The design is then sliced into thin cross-sections, which are sent to the 3D printer. The printer then builds the object layer by layer until it is complete.

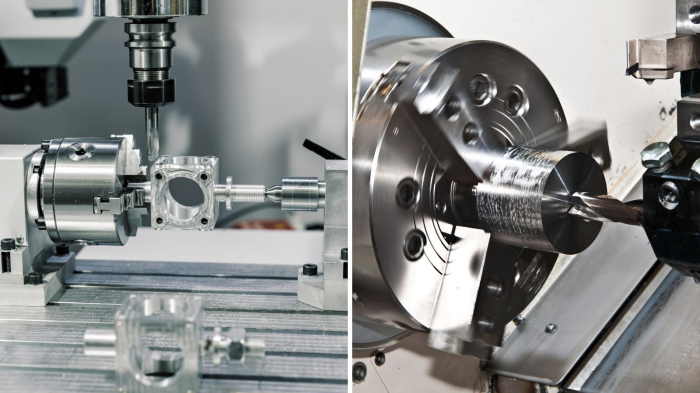

Unlike traditional manufacturing methods such as injection molding or subtractive manufacturing that involve cutting, drilling, or carving materials, 3D printing adds material layer by layer. This makes it a more efficient process as there is minimal waste of raw materials.

Moreover, 3D printing allows for the use of various materials such as plastics, metals, ceramics, and even food products. This versatility in material options gives manufacturers more flexibility in design and functionality.

With its ability to create complex designs that would be difficult or impossible with traditional methods, 3D printing has opened up new possibilities for mass production and is changing the way we think about manufacturing.

Advantages of 3D Printing for Mass Production

There are numerous advantages of using 3D printing for mass production compared to traditional methods. Here are some of the key benefits:

Increased Speed

One of the primary advantages of 3D printing for mass production is its ability to significantly increase production speed. Traditional manufacturing methods often involve multiple steps and processes, which can be time-consuming. In contrast, 3D printing eliminates many of these steps and produces objects in a fraction of the time.

Moreover, with traditional methods, it can take weeks or even months to create specialized tools and molds for new products. With 3D printing, designs can be quickly produced and modified as needed without the need for expensive tooling. This not only saves time but also reduces costs associated with creating specialized tools.

Additionally, 3D printing allows for the simultaneous production of multiple products, further increasing speed and efficiency. This is particularly beneficial in scenarios where there is high demand for a product or when customizations are required.

Lower Costs

Another significant advantage of 3D printing for mass production is its potential to lower manufacturing costs. By eliminating the need for specialized tools and molds, manufacturers can save on upfront costs associated with traditional methods.

Moreover, 3D printing allows for the use of less material compared to subtractive manufacturing methods where excess material is often discarded. This not only reduces waste but also lowers material costs.

Furthermore, as 3D printers become more advanced and cost-effective, it becomes feasible for manufacturers to have multiple printers running simultaneously, further increasing efficiency and reducing labor costs.

Improved Customization

3D printing allows for high levels of customization that would be difficult or impossible with traditional manufacturing methods. With 3D printing, each product can be individually designed and produced without the need for costly tooling changes.

This level of customization is particularly beneficial in industries such as healthcare, where personalized products are needed to fit specific patient needs. It also allows for the creation of unique and complex designs that were previously not possible.

Moreover, modifications to designs can be easily made, allowing for quick iterations and improvements. This flexibility gives manufacturers more creative freedom and helps them meet changing consumer demands.

Reduced Waste

Traditional manufacturing methods often generate a significant amount of waste, whether it be from excess material or rejected products. This not only adds to production costs but also has negative environmental impacts.

In contrast, 3D printing is an additive process that uses only the necessary amount of material required for each product. This reduces waste and makes the production process more sustainable. Furthermore, as 3D printing allows for the use of recycled materials, it can contribute to a circular economy by reducing reliance on new raw materials and minimizing waste generation.

Enhanced Design Freedom

With its advanced capabilities, 3D printing allows for more design freedom compared to traditional manufacturing methods. Designs in 3D printing can be intricate and complex, with no limitations on geometric shapes or sizes.

Moreover, the layer-by-layer production process of 3D printing allows for the creation of internal structures and cavities that would be impossible to achieve with traditional methods. This enables designers to create lighter and more functional products.

Additionally, 3D printing also allows for the incorporation of multiple materials into a single product. This opens up new possibilities for creating products with varying properties and functionalities.

Faster Prototyping

Prototyping is an essential aspect of product development, and 3D printing has revolutionized the process. With traditional methods, creating a prototype can be time-consuming and costly.

In contrast, 3D printing allows for the quick production of prototypes without the need for specialized tooling or molds. This enables manufacturers to test different designs and make modifications efficiently before moving on to mass production.

Furthermore, with its ability to create highly detailed and accurate prototypes, 3D printing reduces the risk of errors in product design. This ultimately leads to cost savings by avoiding potential rework or recalls due to design flaws.

On-Demand Production

3D printing has the potential to revolutionize supply chain management by enabling on-demand production. With traditional manufacturing methods, companies must produce products in bulk and store them until they are needed.

In contrast, 3D printing allows for the production of goods as they are needed, reducing the need for inventory storage and associated costs. This also enables companies to quickly respond to changes in demand or unforeseen circumstances.

Moreover, with its ability to create customized products efficiently, 3D printing opens up opportunities for mass customization. This means that each product can be tailored to individual customer needs without the added time and costs associated with traditional customization methods.

Why 3D Printing is the Future of Mass Production

The advancements in 3D printing technology have significantly impacted mass production processes and are poised to continue doing so in the future. With its numerous advantages, it has become clear that 3D printing is the way forward for manufacturing industries.

Not only does it offer faster production speeds, but it also allows for lower costs, improved customization, reduced waste, enhanced design freedom, faster prototyping, and on-demand production. These benefits not only lead to cost savings and increased efficiency but also open up new opportunities for innovation and creativity.

Furthermore, as 3D printing technology continues to advance and become more accessible, we can expect to see even more significant impacts on the manufacturing industry. With its potential for mass customization and on-demand production, we may soon see a shift towards agile and sustainable supply chains.

Also, as 3D printing becomes more prevalent in industries such as healthcare and aerospace, we can expect to see revolutionary changes in product design and development. Ultimately, 3D printing is set to revolutionize mass production and shape the future of manufacturing.

Contact Breton Precision For Your Custom 3D Printing Needs

Breton Precision offers state-of-the-art custom 3D printing services, utilizing top-notch technologies such as Picky Laser Melding, Stereo Print, HP Multiple Jet Fusion, and Picky Laser Fusing. Our team of experts is dedicated to providing fast and accurate 3D prints and end-use components for both small and large-scale production needs.

We offer a wide range of materials including plastic and metal options like ABS, PA (Nylon), Aluminum, and Stainless Steel to cater to diverse industrial applications. Additionally, we can source other specific materials upon request.

With our state-of-the-art equipment and facilities, we specialize in CNC machining, plastic injection molding, sheet metal fabrication, vacuum casting, and 3D printing. Our team of experts can handle projects ranging from prototype production to mass production with ease.

Need custom 3D printed parts for your project? Contact Breton Precision today at +86 0755-23286835 or info@breton-precision.com. Our professional and dedicated team will be happy to assist you with all your custom 3D printing needs.

FAQs

How does 3D printing compare to traditional manufacturing processes for rapid prototyping?

3D printing excels in rapid prototyping compared to traditional manufacturing processes by allowing for faster and more cost-effective development of prototypes. This additive manufacturing process enables designers to create complex models within hours, significantly speeding up the iteration cycles necessary in the manufacturing process.

Can 3D printing be used for high volume production like other manufacturing processes?

Yes, 3D printing can be used for high volume production. While it was traditionally used for prototyping, advancements in additive manufacturing processes have enabled it to support mass manufacturing. This is particularly advantageous when producing complex, lightweight designs where conventional manufacturing methods would be less efficient or more costly.

What are the benefits of using 3D printing over conventional manufacturing methods for mass production?

3D printing offers several benefits over conventional manufacturing methods for mass production, including greater flexibility in design, reduced waste, and lower overhead costs. Unlike traditional manufacturing techniques that often require expensive molds and tools, the additive manufacturing process builds objects layer by layer, allowing for the economical production of complex geometries without additional costs.

How does the additive manufacturing process enhance the overall manufacturing process?

The additive manufacturing process enhances the overall manufacturing process by allowing for the direct construction of parts from digital files, reducing the time and cost associated with traditional manufacturing techniques. This process not only simplifies the production of complex and customized items but also allows companies to mass produce parts on-demand, improving supply chain efficiency and reducing inventory costs.

Conclusion

The future of mass production lies in the hands of 3D printing technology. With its numerous benefits, it has opened up opportunities for faster prototyping, on-demand production, and mass customization.

As this technology continues to advance and become more accessible, we can expect to see even more significant impacts on the manufacturing industry.

At Breton Precision, we are committed to staying at the forefront of this revolution and providing superior custom 3D printing services to meet our clients' evolving needs. Contact us today to learn more about our services and how we can help bring your ideas to life with precision and efficiency.

Related searches: Kinds Of 3d Printers Design Of 3d Printer Abs Material In 3d Printing