Application Of 3D Printing In Medical Devices

3D printing, also known as additive manufacturing, has revolutionized the world of medical devices. It is a process of creating three-dimensional objects from a digital file by adding layer upon layer of material until the desired shape is formed.

The use of this technology in the medical field offers numerous benefits such as faster production times, customization, cost-effectiveness, and improved patient outcomes. 3D printing has transformed the way medical devices are designed, manufactured and used.

This innovative technology has enabled healthcare professionals to provide more personalized treatment options to patients while also reducing costs and improving efficiency.

What is 3D printing and how does it work?

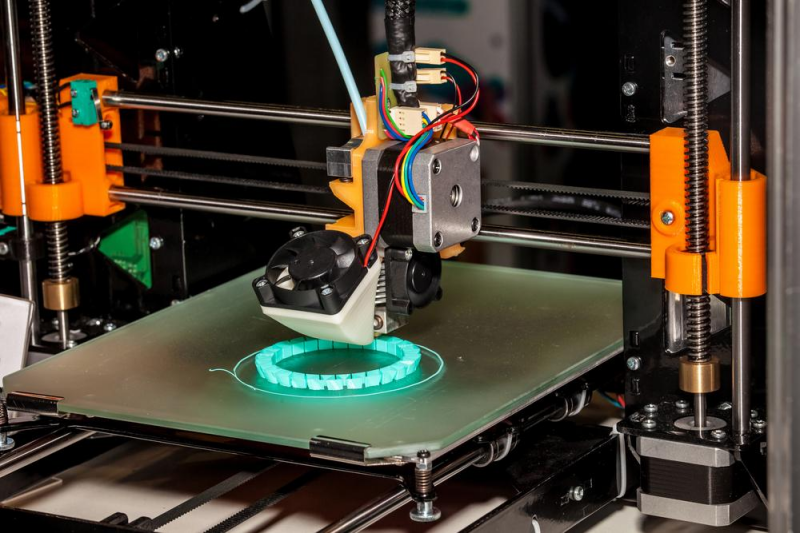

3D printing is an additive manufacturing process that involves building objects layer by layer using a digital file as a blueprint. The process starts with creating a 3D model using computer-aided design (CAD) software, which is then sliced into thin layers to be printed one at a time.

The first step in the 3D printing process is to choose the material for the object. Different types of materials such as plastic, metal, and even living cells can be used depending on the purpose of the final product. The chosen material is then fed into the printer in either liquid, powder or filament form.

Once all the materials are in place, the printer starts building the object layer by layer. This is achieved through a variety of 3D printing technologies such as fused deposition modeling (FDM), stereolithography (SLA), selective laser sintering (SLS), and digital light processing (DLP). Each technology has its own unique process but they all follow the same principle of adding layers until the final product is created.

After the printing is completed, any support structures are removed and finishing touches such as polishing or painting can be done to achieve the desired look and functionality of the object. This entire process can take anywhere from a few hours to several days depending on the complexity and size of the object.

3D printing has transformed traditional manufacturing processes by making it possible to create complex shapes and intricate designs that were previously not feasible with traditional methods. This flexibility and versatility make 3D printing an ideal technology for medical device fabrication.

Applications of 3D Printing in Medical Devices

The use of 3D printing in medical devices has opened up a world of possibilities and advancements in the healthcare industry. From prosthetics to surgical tools, 3D printing is being utilized in various areas of medicine. Here are some common applications of 3D printing in medical devices:

Customized Prosthetics

One of the most significant advantages of 3D printing in medical devices is the ability to create fully customized prosthetics for patients. Traditional prosthetics are often uncomfortable and can cause skin irritations due to their generic design. With 3D printing, prosthetics can be designed and produced according to a patient's specific measurements, ensuring a perfect fit and increased comfort.

Plus, 3D printing allows for the creation of prosthetics with intricate and detailed designs that closely resemble natural body parts. This gives amputees a sense of normalcy and boosts their self-confidence.

Additionally, 3D printing is a cost-effective solution for creating prosthetics. Traditional methods required expensive molds and manual adjustments, which can be time-consuming and costly. With 3D printing, prosthetic limbs can be produced in a matter of hours at a fraction of the cost.

Surgical Models and Guides

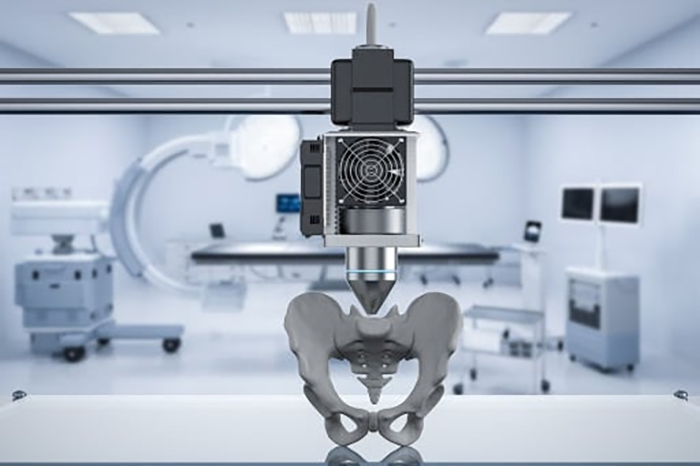

Another significant application of 3D printing in medical devices is the creation of surgical models and guides. These are replicas or representations of a patient's anatomy that doctors can use to plan surgeries or practice complex procedures before performing them on the actual patient.

With traditional methods, surgeons would have to rely on 2D images from scans and X-rays to visualize the patient's anatomy. However, with 3D printing, a precise model of the patient's body can be created, allowing surgeons to get a better understanding of the problem and plan accordingly.

Similarly, surgical guides can be 3D printed to assist surgeons during operations. These guides are personalized for each patient and provide a roadmap for the procedure, reducing the risk of errors and complications.

Prosthetics and Implants

The use of 3D printing in prosthetics and implants has revolutionized the field of orthopedics. With traditional methods, creating custom-fit implants or replacements was a time-consuming process that required extensive manual labor. However, with 3D printing, these devices can be produced quickly and accurately.

Moreover, 3D printing allows for the creation of complex and lightweight designs that are not possible with traditional methods. This is particularly beneficial for patients who require joint replacements as they can move more naturally with lighter prostheses.

Hearing Aids

Traditionally, hearing aids were bulky and uncomfortable due to their one-size-fits-all design. However, with 3D printing, they can now be designed and produced according to the specific shape of a patient's ear canal.

This customization not only improves comfort but also enhances the effectiveness of the hearing aid by reducing sound leakage. Plus, 3D printing allows for the creation of intricate designs that are barely visible when worn, making them more aesthetically pleasing.

Plus, 3D printing also makes it easier and faster to replace damaged or lost hearing aids as they can be reproduced on-demand.

Dental Devices

The use of 3D printing in dentistry has greatly improved the accuracy and efficiency of creating dental devices. With traditional methods, creating braces, retainers and other orthodontic devices required multiple appointments and manual adjustments. However, with 3D printing, these devices can be produced quickly and precisely based on digital scans of a patient's teeth.

Moreover, 3D printing allows for the creation of biocompatible materials for dental implants that closely resemble natural teeth. This not only improves the aesthetics but also increases the longevity of the implant.

Tissue and Organ Printing

Perhaps one of the most exciting applications of 3D printing in medical devices is its potential for tissue and organ printing. Currently, researchers are working on developing methods to print tissues and even entire organs using a patient's own cells.

This could potentially revolutionize organ transplants by eliminating the need for donors and reducing waiting times for patients in need. It could also address issues of transplant rejection as the organs would be created from a patient's own cells.

Additionally, 3D printing tissues could be used for drug testing and personalized medicine, allowing doctors to test the effectiveness of a treatment on a patient's specific tissue before administering it.

So these are just some of the many ways in which 3D printing is transforming the medical device industry. With continuous advancements and research, we can expect to see even more innovative uses of this technology in the field of medicine.

How 3D Printing is Advancing Healthcare

Apart from the specific applications mentioned above, 3D printing is also advancing healthcare in general by increasing accessibility and efficiency. With traditional methods, certain medical devices and treatments were only available to a limited number of patients due to high costs or lack of availability. However, with 3D printing, these medical devices produced can be produced quickly and at lower costs, making them more accessible to a wider population.

Moreover, 3D printing allows for the creation of patient-specific solutions that are tailored to their unique needs. This not only improves comfort but also increases the effectiveness of treatments and reduces the risk of complications.

Additionally, 3D printing is also driving innovation in the medical field by allowing for more experimentation and customization. As researchers and scientists continue to explore the capabilities of this technology, we can expect to see even more breakthroughs in healthcare.

Furthermore, 3D printing has the potential to impact global healthcare positively. With its ability to produce medical devices and supplies on-demand, it could help address shortages in developing countries or emergency situations.

Does 3D Printing Have Limitations in Healthcare?

While 3D printing has shown tremendous potential in advancing healthcare, it also has its limitations. One of the main concerns is the quality and safety of materials used in 3D printing. As these devices are implanted or used within the human body, it is crucial that they meet strict standards and do not pose any health risks.

Moreover, there is still a lack of long-term studies on the effectiveness and safety of 3D printed medical devices. This makes it difficult to fully understand their impact and potential risks.

Another limitation is the high cost of 3D printers and materials, which can make it challenging for smaller medical facilities to adopt this technology. This could create a divide in healthcare access between larger, well-funded institutions and smaller ones.

Additionally, 3D printing has certain limitations when it comes to creating complex tissues or organs with multiple functionalities. While research is ongoing in this area, it may still be some time before we see significant advancements in tissue and organ printing.

Mistakes in 3D Printing and Their Impact on Healthcare

As with any technology, there is always the possibility of human error when it comes to 3D printing. Here are some of the most common mistakes in 3D printing and how they can impact healthcare:

- Incorrect design or programming: A small mistake in designing or programming a 3D printed medical device can lead to significant flaws that could harm patients. This is why it is crucial to have professionals with proper training and knowledge overseeing the process. Plus, thorough testing and quality control measures should be in place to ensure the accuracy and safety of the final product.

- Use of faulty or incorrect materials: The use of substandard materials can result in medical devices that are not biocompatible or strong enough to withstand their intended use. This could lead to complications such as infections or breakage, which could have serious consequences for patients. Plus, using the wrong materials could also impact the accuracy and effectiveness of 3D printed tissues or organs.

- Lack of standardization: As 3D printing is still a relatively new technology in healthcare, there are currently no standardized protocols or regulations in place. This can lead to inconsistencies in quality and safety across different medical facilities, potentially putting patients at risk.

- Inadequate training and oversight: Proper training and supervision are crucial for those involved in the 3D printing process, from design to production. Without proper knowledge and experience, mistakes are more likely to happen, which could compromise the safety of medical devices and tissues created through 3D printing.

- Lack of post-production testing: It is essential to conduct thorough testing after the production of 3D printed medical devices or tissues. This ensures that they meet quality standards and function as intended, reducing the risk of adverse effects on patients.

While these mistakes can have serious consequences in healthcare, they can be prevented through proper training, protocols, and regulations. As 3D printing continues to evolve and become more prevalent in the medical industry, it is crucial to address and mitigate these potential risks.

Is 3D Printing the Future of Healthcare?

The potential benefits and advancements of 3D printing in healthcare are undeniable. However, it is still a relatively new technology with limitations and risks that need to be addressed. While it may not be the sole future of healthcare, 3D printing has undoubtedly changed the landscape of medicine and will continue to play a significant role in its evolution.

As research and development continue to push the boundaries of this technology, we can expect to see even more innovative uses for 3D printing in healthcare. From personalized medical devices to complex tissues and organs, the possibilities are endless.

Moreover, as 3D printing becomes more accessible and cost-effective, it has the potential to revolutionize healthcare globally. It could help bridge the gap between developed and developing countries in terms of medical access and supply shortages. Plus, with its ability to produce on-demand and customizable solutions, 3D printing could significantly improve patient outcomes and quality of life.

Contact Breton Precision For Your 3D Printing Needs

At Shenzhen Breton Precision Model Co., Ltd, we pride ourselves on offering a comprehensive range of one-stop processing services for manufacturing requirements. Our team is well-equipped to handle projects ranging from prototype production to mass production with our advanced manufacturing capabilities.

We have established ourselves as a leading on-demand manufacturing company in China through our dedication to strict quality control and adherence to high tolerance standards.

We offer 3D printing services for a variety of technologies, including SLA, SLS, and SLM. Our quick production process allows us to efficiently produce silicone molds with up to 20 products within a short timeframe. We also provide sheet metal services for low-volume metal projects.

We also specialize in CNC machining, plastic injection molding, sheet metal fabrication, vacuum casting, and 3D printing. Our team of experts can handle projects ranging from prototype production to mass production with ease.

So call us at 0086 0755-23286835 or email us at info@breton-precision.com to discuss your manufacturing needs. Our professional team will work closely with you to provide the best solutions for your project, ensuring timely delivery and exceptional quality products.

FAQs

How does 3D printing improve the production of patient-specific medical devices compared to traditional manufacturing methods?

3D printing offers significant advantages over traditional manufacturing methods for producing medical devices and patient-specific medical devices. This technology allows for rapid prototyping and production, enabling medical professionals to customize devices to the specific anatomical needs of patients, which is crucial in surgical procedures and treatments.

What are the benefits of 3D printing surgical instruments for medical applications?

3D printing surgical instruments for medical applications allows for more precise and tailored tools that meet the specific needs of surgical procedures. This method not only speeds up the production process but also enhances the functionality of the instruments, potentially improving outcomes for patients and the efficiency of medical professionals during surgery.

How are medical students benefiting from 3D printing technology?

Medical students benefit from 3D printing technology by gaining access to more detailed and accurate anatomical models and surgical tools for practice. These resources enhance their learning experience by providing hands-on exposure to patient-specific devices and scenarios they may encounter in their future medical careers.

Can 3D printing be used to create drug delivery devices?

Yes, 3D printing can be used to create innovative drug delivery devices that are tailored to individual patient needs. This technology enables the incorporation of patient-specific data, such as those derived from magnetic resonance imaging (MRI), to design devices that can precisely control the dosage and release rates of medications, improving treatment efficacy and patient safety.

Conclusion

In conclusion, 3D printing has the potential to greatly improve healthcare by offering personalized solutions and addressing supply shortages. However, it is crucial to address the risks and limitations of this technology through proper training, protocols, and regulations.

Also, by partnering with a reliable and experienced manufacturing company like Breton Precision, you can ensure the highest quality products for your 3D printing needs. Our commitment to excellence and customer satisfaction makes us a top choice for on-demand manufacturing services in China.

Related searches: Types Of 3 D Printing Parts Of Fdm 3d Printer Plastic Used In 3d Printing