metal x 3d printer cost

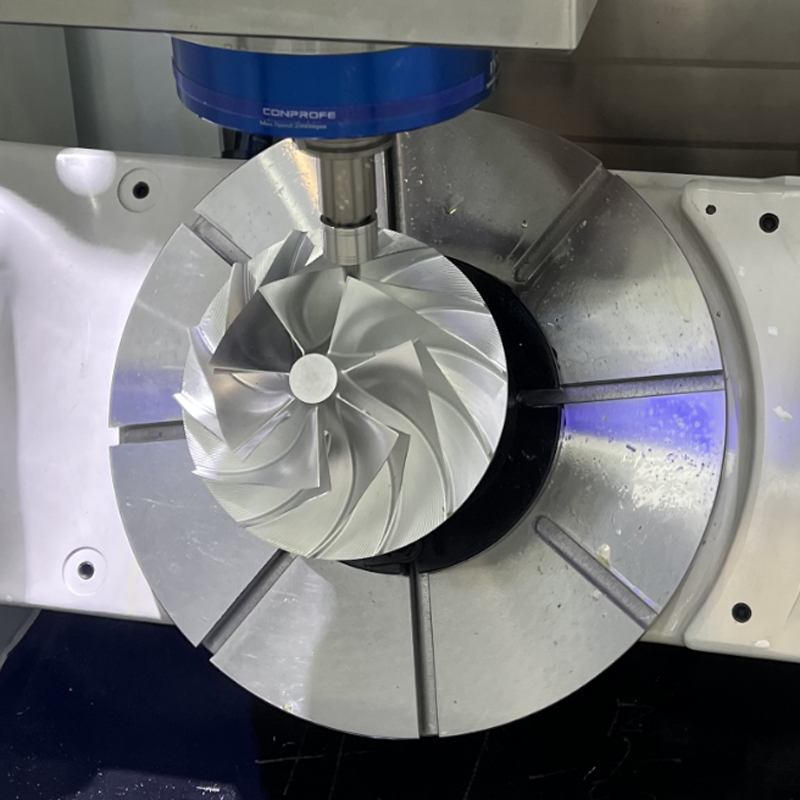

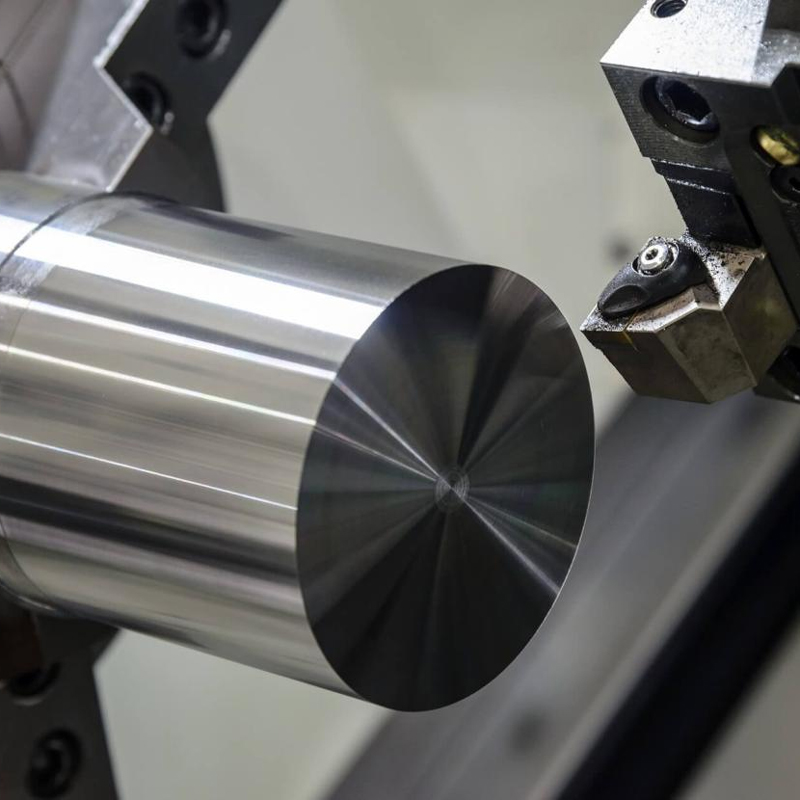

When considering the cost of a Metal X 3D printer, it's essential to understand that the price tag reflects not just the hardware but also the technology, capabilities, and potential value it brings to its users. The Metal X, a metal 3D printer designed for professional and industrial applications, represents a significant investment for those seeking to enter the world of metal additive manufacturing.At the core of the Metal X's pricing is the advanced hardware and technology it employs. The printer utilizes laser powder bed fusion (LPBF) technology, which involves melting metal powder layer by layer to build up a solid object. This process requires precision lasers, sophisticated motion control systems, and a tightly controlled build chamber to ensure consistent and high-quality prints. The combination of these components drives up the initial purchase price of the Metal X.In addition to the hardware, metal 3D printing also involves the cost of materials. Metal powders used in LPBF printing can be expensive, depending on the type of metal and its purity. Common metals used in Metal X printing include stainless steel, titanium, and aluminum, each with its own cost range. Users should factor in the cost of these materials, as well as any additional powders needed for calibration or testing, into their overall budget.Once the Metal X is in operation, there are additional costs to consider. Regular maintenance, such as cleaning the build chamber and replacing worn-out parts, is crucial for maintaining the printer's performance. These costs can vary depending on usage and the specific model of the printer. Additionally, consumables like filters and lubricants may need to be replaced periodically.