what is injection molding

Injection molding, also known as injection moulding, is a manufacturing process for producing parts by injecting molten material into a mold, or mold cavity, where it cools and solidifies to conform to the shape of the cavity. This process is widely used in the production of a variety of plastic parts, as well as some metal and ceramic parts, for a diverse range of industries including automotive, electronics, medical, and consumer goods.

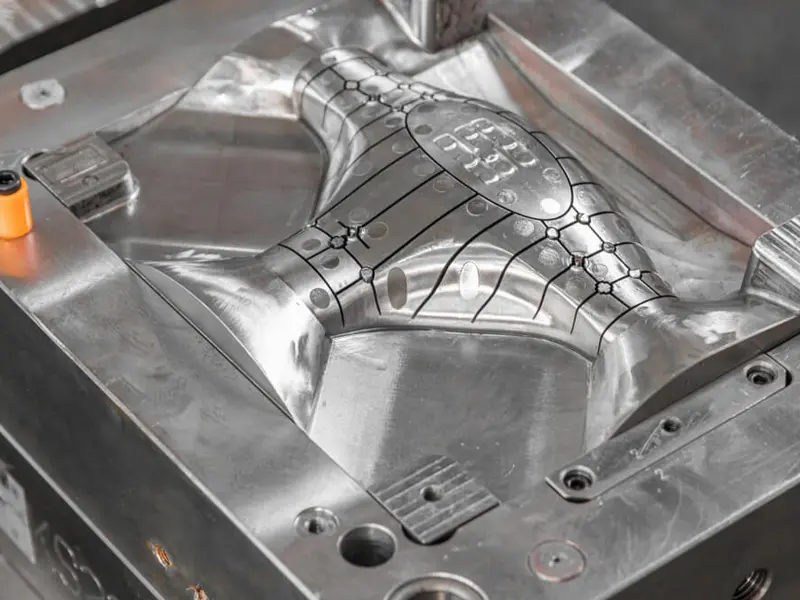

In the injection molding process, a plastic material is heated to a molten state and then forced into a mold cavity under high pressure by an injection molding machine. The mold typically consists of two halves, which are clamped together to form the desired shape of the part. Once the molten plastic has filled the cavity, the pressure is maintained for a brief period to allow the plastic to cool and solidify. The mold is then opened, and the finished part is ejected from the mold.

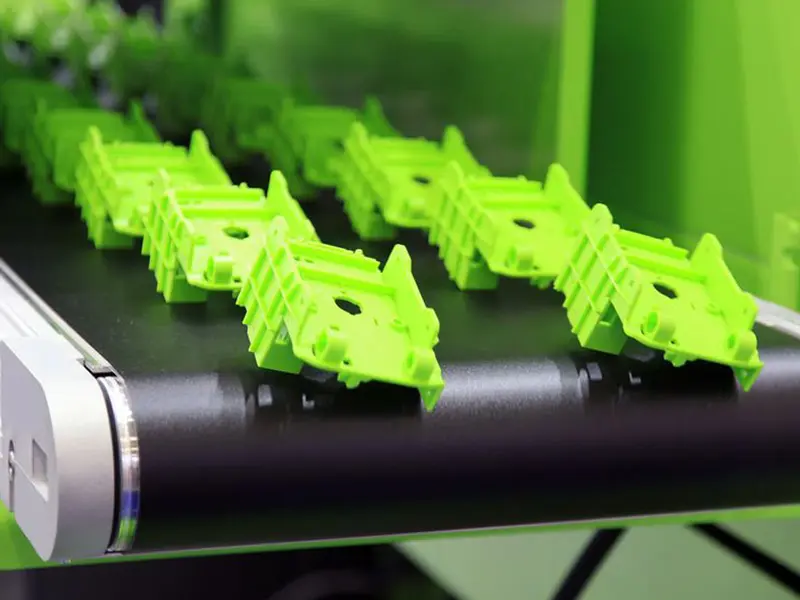

The injection molding process offers several advantages, including the ability to produce parts with complex shapes and features, high production rates, and the potential for cost savings due to economies of scale. Additionally, the process allows for precise control over the dimensions and properties of the final product, making it well-suited for mass production of parts with tight tolerances and high quality standards.

In summary, injection molding is a widely used manufacturing process that involves injecting molten material into a mold cavity to produce parts with precise dimensions and complex shapes. This process is highly efficient and cost-effective, making it an attractive choice for a variety of industries.

Related searches: rapid injection molding metal injection molding ODM Injection Molding Mold Suppliers