is 3d printing cost effective

is 3d printing cost effective? whether 3D printing is cost-effective depends on several factors, including the specific application, the material used, the quantity of parts being produced, and the production process being compared against. Here's a closer look at the cost-effectiveness of 3D printing in different contexts:

Advantages of Cost-Effectiveness

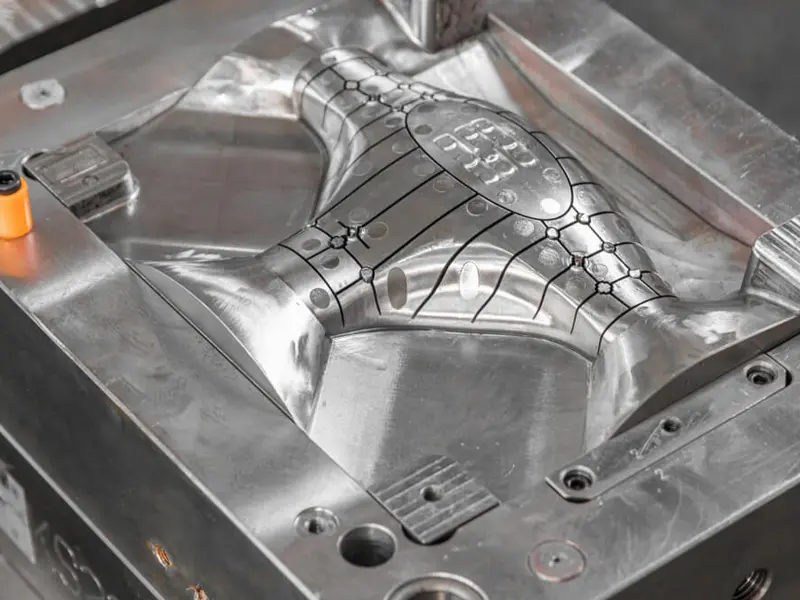

Low-Volume Production: For low-volume production runs, 3D printing can be highly cost-effective. Traditional manufacturing methods, such as injection molding, often require significant upfront costs for mold creation, which can be prohibitively expensive for small production runs. In contrast, 3D printing allows for the production of individual parts or small batches without the need for expensive tooling.

Customization: 3D printing enables high levels of customization, allowing for the production of unique or personalized parts. This can be particularly cost-effective in applications where each part must be tailored to specific requirements or preferences.

Rapid Prototyping: For designers and engineers, 3D printing provides a fast and cost-effective way to create prototypes and iterate on designs. The ability to quickly produce and test physical prototypes can help reduce the overall development time and cost by minimizing the need for expensive and time-consuming production runs of traditional prototypes.

Reduced Waste: 3D printing often involves the use of additive manufacturing techniques, where material is added layer by layer to create a part. This can lead to reduced waste compared to subtractive manufacturing methods, such as milling or cutting, which often require the removal of excess material.

Disadvantages of Cost-Effectiveness

High Material Costs: In some cases, the material costs associated with 3D printing can be relatively high compared to traditional manufacturing methods. Depending on the material used and the quantity of parts being produced, the cost per part may not be competitive.

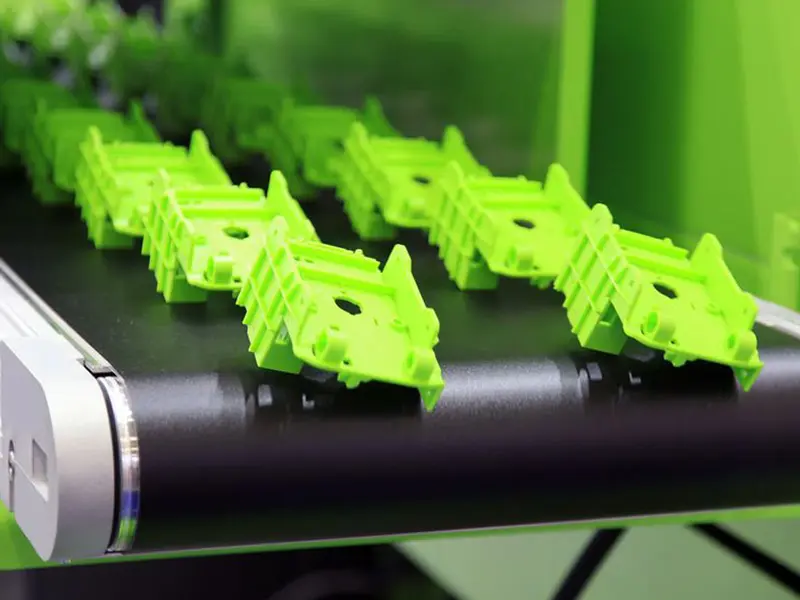

Limited Production Speed: While 3D printing is capable of producing parts quickly, it may not be as fast as some traditional manufacturing methods when it comes to producing large quantities of identical parts. This can make 3D printing less cost-effective for high-volume production runs.

Post-Processing Costs: Some 3D-printed parts may require additional post-processing steps, such as sanding, painting, or assembly, which can add to the overall cost.

Equipment Costs: The initial investment in 3D printing equipment can be significant, especially for high-end industrial printers. While this cost can be offset over time by the savings realized from rapid prototyping and low-volume production, it may not be feasible for all businesses or individuals.

the cost-effectiveness of 3D printing depends on the specific application and the production process being compared against. For low-volume production, customization, and rapid prototyping, 3D printing can be highly cost-effective. However, for high-volume production runs, traditional manufacturing methods may be more cost-effective due to their higher production speeds and lower material costs. Ultimately, the decision to use 3D printing should be based on a careful analysis of the specific requirements and constraints of the application.

Related searches: Kinds Of 3d Printers Design Of 3d Printer Abs Material In 3d Printing