how to make a hard plastic mold

Makeing a hard plastic mold is a meticulous and intricate process that involves several critical stages, including design, material selection, manufacturing, assembly, and debugging. Here's a concise overview of the process:

Design Phase:

The process begins with a thorough understanding of the product's requirements, including its shape, dimensions, material, and intended function. Utilizing CAD (Computer-Aided Design) software, a 3D model of the product is created, serving as the foundation for the mold design. The mold design must account for the product's features, parting lines, gate locations, and other critical elements to ensure successful molding.

Material Selection:

The choice of mold material is crucial, as it determines the mold's durability, precision, and longevity. Hardened steel alloys like SKD61, NAK80, or P20 are commonly used for hard plastic molds due to their high strength, wear resistance, and heat tolerance. These materials can withstand the rigors of the injection molding process, ensuring accurate and repeatable results.

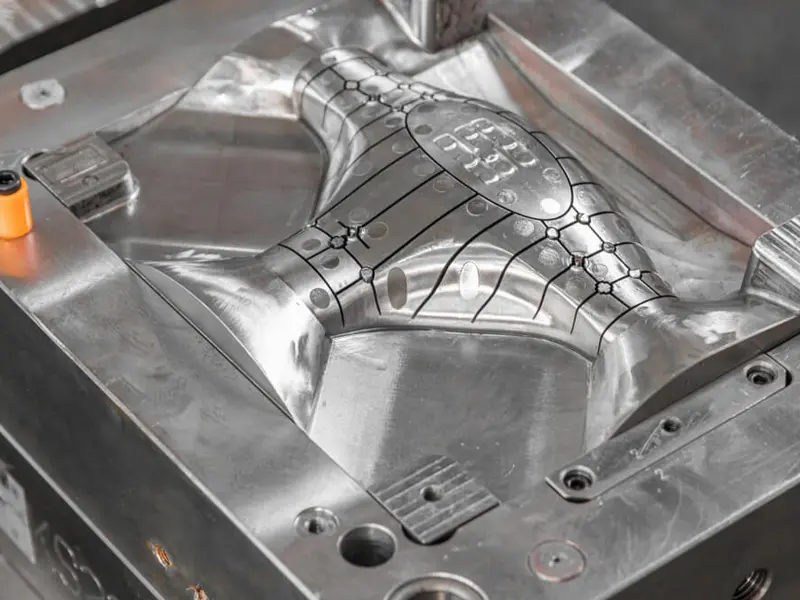

Manufacturing Phase:

The manufacturing phase involves transforming the mold design into a physical mold through various precision machining and finishing techniques. This typically includes milling, grinding, electrical discharge machining (EDM), wire electrical discharge machining (WEDM), and other specialized processes. High-precision machine tools and skilled technicians are essential to ensure that the mold's dimensions, surface finish, and features meet the design specifications.

Assembly:

Once all mold components are manufactured, they are carefully assembled. This process involves aligning and securing the mold halves, installing ejector pins and other mold components, and ensuring that the mold functions smoothly. Accurate assembly is crucial for achieving successful and repeatable molding results.

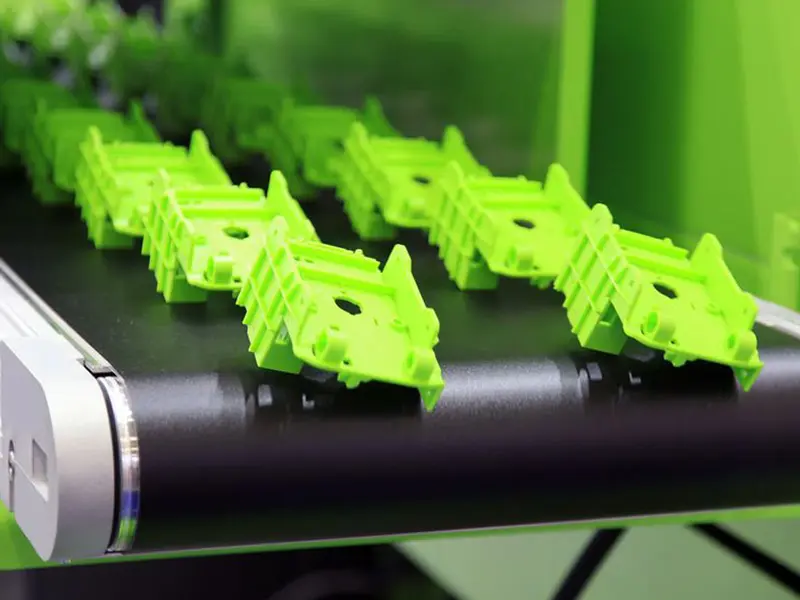

Debugging and Testing:

After assembly, the mold undergoes a series of tests and adjustments to identify and resolve any issues that may affect its performance. This includes checking the mold's alignment, gate balance, and cooling efficiency. A trial run using actual plastic material is conducted to evaluate the mold's ability to produce parts that meet the desired quality standards. Any necessary adjustments or repairs are made based on the results of these tests.

Maintenance and Care:

Once the mold is in production, regular maintenance and care are essential to maintain its performance and extend its lifespan. This includes cleaning the mold to remove residue and debris, lubricating moving parts, and inspecting for wear or damage. Timely repairs and replacements of worn-out components can help prevent costly downtime and ensure continuous, high-quality production.

Makeing a hard plastic mold is a comprehensive process that requires careful planning, precision manufacturing, and ongoing maintenance. By adhering to these principles, manufacturers can produce molds that consistently deliver high-quality plastic parts, meeting the demands of a wide range of industries and applications.

Related searches: rapid injection molding metal injection molding ODM Injection Molding Mold Suppliers