how much does injection molding cost

Injection molding costs can vary significantly depending on various factors, including the complexity of the part, the material used, the production volume, and the location of the manufacturer. Here's a comprehensive overview of the primary factors that influence injection molding costs and how they contribute to the overall expense:

1. Part Complexity:

The complexity of the plastic part plays a significant role in determining the cost of injection molding. Complex parts with intricate details, undercuts, or multiple undercuts require more sophisticated mold designs and potentially additional manufacturing steps, such as slide mechanisms or lifters, which increase the mold's cost.

2. Material Costs:

The choice of plastic material directly impacts the cost of injection molding. Different materials vary in price, with some being more expensive than others due to factors like raw material costs, availability, and demand. The cost of the material is usually calculated based on the weight of the part and the material's price per kilogram or pound.

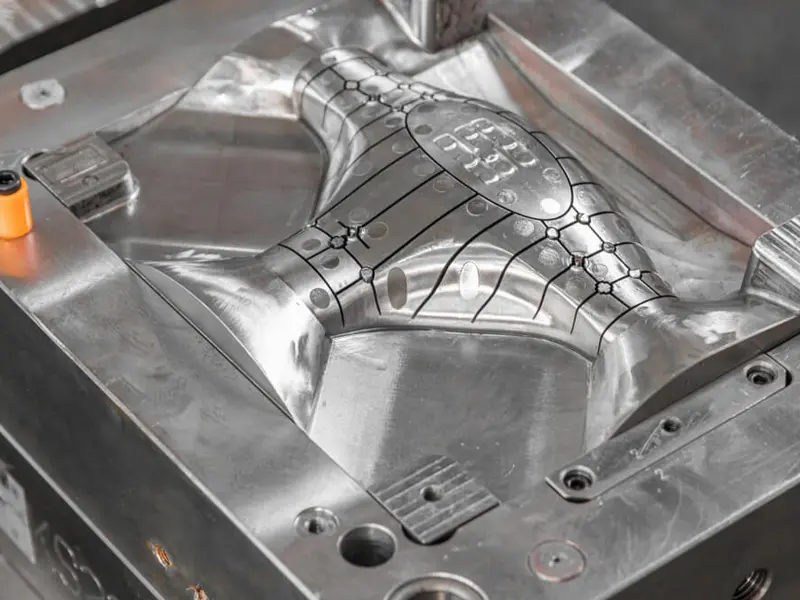

3. Mold Costs:

The mold is a critical component of the injection molding process, and its cost can be substantial, especially for complex parts. Mold costs can range from a few thousand dollars for simple molds to tens or even hundreds of thousands of dollars for highly complex molds. The mold's cost is a fixed cost that is amortized over the production run, making it less significant for large-volume production.

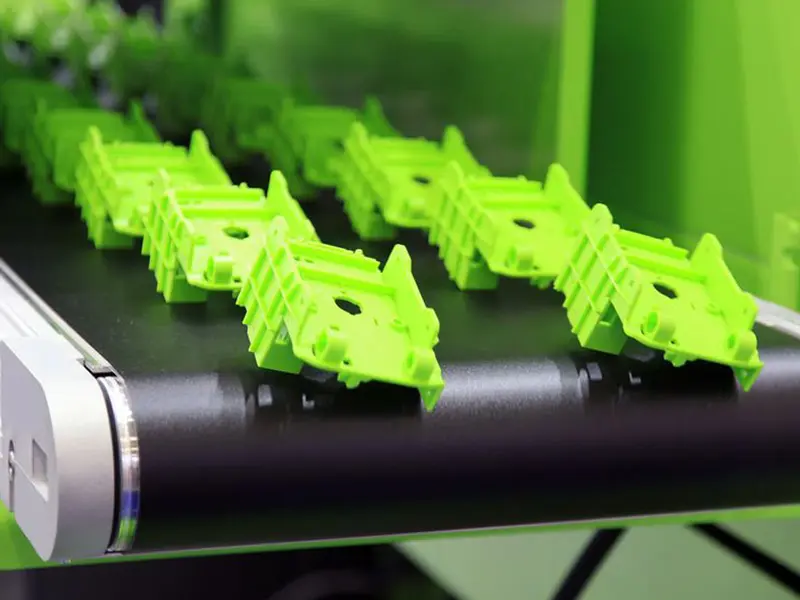

4. Production Volume:

The production volume also affects the cost of injection molding. Higher production volumes allow for the amortization of fixed costs, such as mold costs, over a larger number of parts, resulting in lower per-part costs. Conversely, low-volume production runs may have higher per-part costs due to the inability to fully amortize fixed costs.

5. Labor and Overhead Costs:

Labor and overhead costs, including wages, benefits, equipment maintenance, and facility expenses, also contribute to the overall cost of injection molding. These costs can vary depending on the location of the manufacturer and the local labor market conditions.

6. Additional Costs:

Depending on the specific requirements of the part, additional costs may be incurred, such as secondary operations like painting, plating, or assembly. These costs are typically added to the base injection molding cost.

7. Market Conditions and Supplier Negotiations:

Market conditions, such as supply chain disruptions or raw material shortages, can also impact injection molding costs. Additionally, suppliers may offer different pricing structures or discounts based on the customer's relationship, order size, or payment terms.

injection molding costs are influenced by a multitude of factors, including part complexity, material costs, mold costs, production volume, labor and overhead costs, additional operations, and market conditions. Accurately estimating the cost of injection molding requires a thorough understanding of these factors and the ability to negotiate with suppliers to obtain the best possible pricing. Due to the variability in these factors, it's essential to work closely with a reputable injection molding manufacturer to obtain a detailed quote tailored to your specific requirements.

Related searches: rapid injection molding metal injection molding ODM Injection Molding Mold Suppliers