how much does 3d printing service cost

The cost of 3D printing services can vary significantly depending on several factors. Here's a comprehensive overview of the key cost components:

1. Design Costs

Definition: The design costs refer to the expenses associated with creating the 3D model using CAD software.

Factors: The cost of design depends on the designer's time, technical expertise, and the complexity of the design.

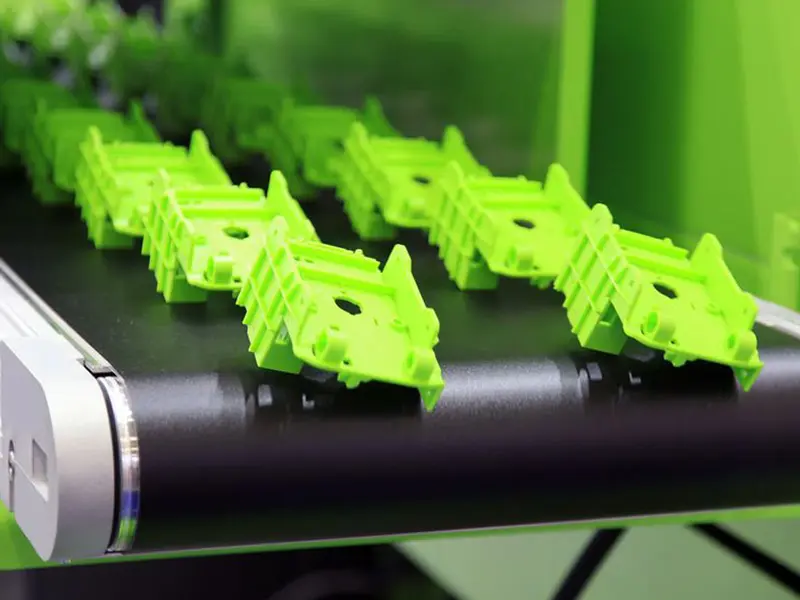

2. Material Costs

Definition: Material costs refer to the expenses incurred for the materials used in 3D printing.

Factors: The type of material (e.g., ABS, PLA, TPU, metal powders, etc.), its quality, supplier, and the weight of the model being printed all impact the material cost. Additionally, the material utilization rate also plays a role.

Example: The cost of titanium alloy, a commonly used metal for 3D printing, can be around $800 per kilogram. However, the actual material cost for a specific project would depend on the model's weight and other factors.

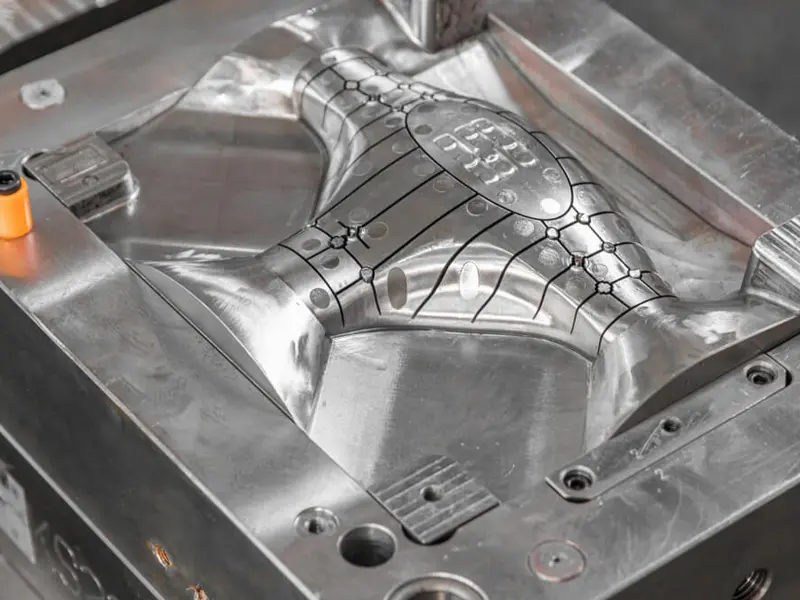

3. Equipment Costs

Definition: Equipment costs encompass the price of the 3D printer, installation fees, electricity consumption, maintenance, and downtime costs.

Factors: The cost of equipment varies widely based on the type (desktop vs. industrial), brand, and functionality of the 3D printer. Industrial-grade printers are typically more expensive and require higher maintenance costs due to their complexity.

Calculation: Hourly equipment costs can be estimated by dividing the printer's price by the estimated investment return time (in hours) and then multiplying by the printing time (in hours).

4. Labor Costs

Definition: Labor costs cover the expenses related to printing preparation and post-processing activities.

Factors: The cost of labor depends on the time required for tasks such as slicing the model into layers, setting up the printer, and post-processing tasks like sanding, painting, etc. The labor rate (including wages and benefits) also impacts the total cost.

Example: According to some industry reports, labor costs can account for a significant portion of the overall 3D printing cost, with estimates ranging from a fraction to a majority of the total cost, depending on the project's complexity and scope.

5. Other Costs

Definition: Other costs may include risks associated with printing failures (leading to material waste and time loss) and maintenance/repair expenses for the 3D printer.

Factors: These costs can vary significantly based on the project's specifics and the printer's reliability.

Comprehensive Cost

Given the complexity and variability of these factors, it's challenging to provide a definitive cost figure for 3D printing services. However, it's essential to consider all these components when estimating the cost of a 3D printing project.

To obtain an accurate cost estimate, it's recommended to consult with a specific 3D printing service provider and discuss the project's requirements, material selection, equipment configuration, and other relevant details. This will help ensure that you have a comprehensive understanding of the expected costs and can make an informed decision about whether 3D printing is the right solution for your project.

Related searches: Kinds Of 3d Printers Design Of 3d Printer Abs Material In 3d Printing