how does injection molding work

Injection molding is a highly efficient and precise manufacturing process that transforms plastic materials into a wide range of products, including toys, automotive parts, electronic components, and many more. The process begins with the preparation of plastic resin, which is fed into an injection molding machine. Inside the machine, the resin is heated to a molten state, where it becomes viscous and flowable. A precisely engineered mold, consisting of two halves that form the desired shape of the product, is clamped together and readied for injection.

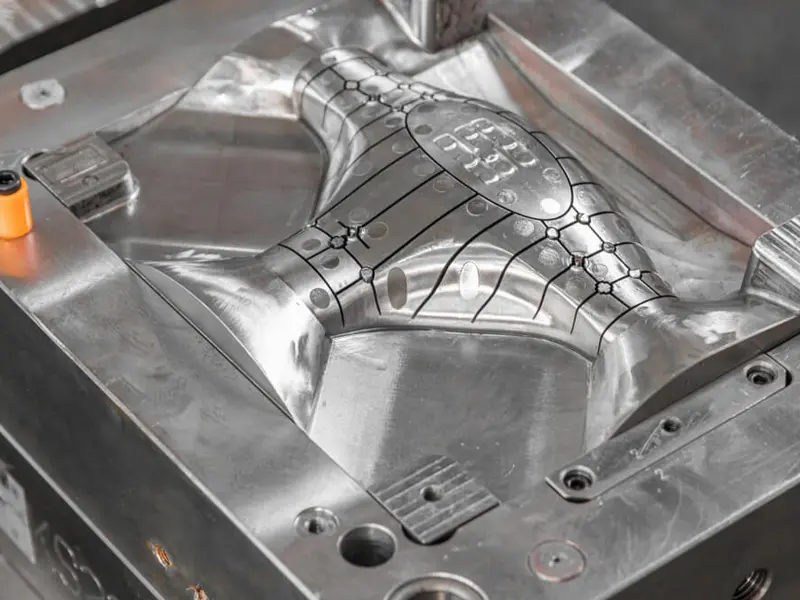

The molten plastic is then forcibly injected into the mold cavity under high pressure, filling every corner and detail of the mold's intricate design. As the plastic cools, it solidifies and takes on the exact shape of the mold cavity. This solidification process is carefully controlled to ensure that the product meets strict quality standards for dimensional accuracy, surface finish, and material properties.

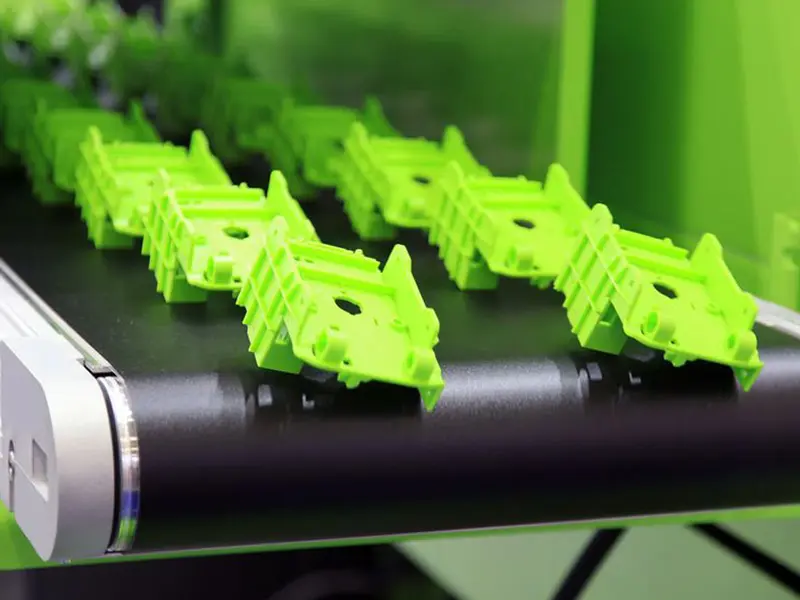

After a brief cooling period, the mold is opened, and the now-solidified plastic product is ejected from the mold. The ejection process is automated and often involves mechanical ejector pins or air blasts to gently dislodge the product from the mold. The product then undergoes post-processing steps, such as trimming excess flash, cleaning, and possibly secondary operations like painting or assembly.

The key to the success of injection molding lies in the precision of the mold design and construction. The mold must be carefully engineered to withstand the high pressures and temperatures of the injection process while maintaining strict tolerances for dimensional accuracy and surface finish. Modern injection molding machines are equipped with advanced controls and sensors that monitor and adjust process parameters in real-time, ensuring consistent product quality and maximizing production efficiency.

Injection molding is an environmentally friendly process as well, as the scrap material generated during production can often be recycled and reused in future molding operations. Overall, injection molding is a versatile, cost-effective, and scalable manufacturing process that enables the production of a vast array of high-quality plastic products in virtually any shape or size.

Related searches: rapid injection molding metal injection molding ODM Injection Molding Mold Suppliers