can metal be 3d printed

Yes, metal can be 3D printed. Metal 3D printing, also known as metal additive manufacturing, is a technology that builds three-dimensional objects by adding layers of metal powder and fusing or sintering them together. This technology enables the creation of complex metal parts with high precision and consistency, and has found applications across various industries.

Technical Principles of Metal 3D Printing

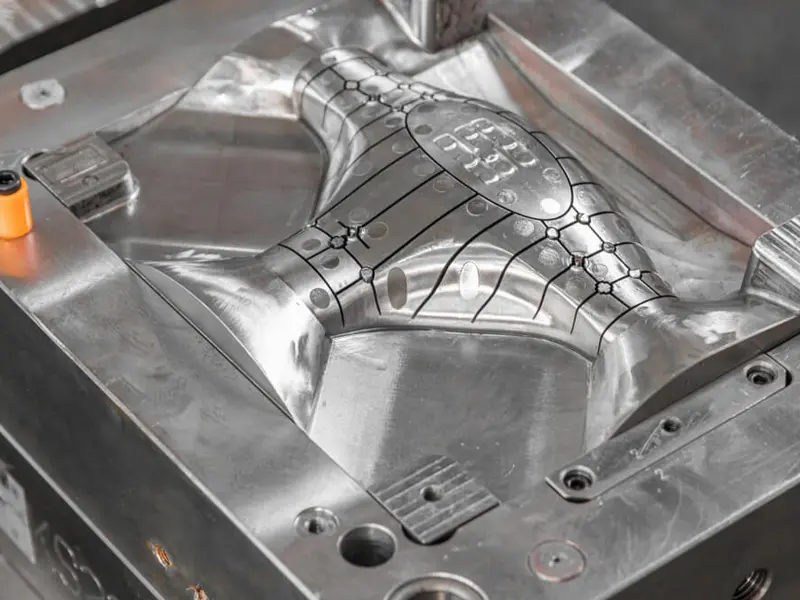

Metal 3D printing processes involve either directly sintering or melting metal powders, or delivering them through a nozzle combined with a second material. This technology allows for the construction of intricate structures that may be difficult or impossible to produce using other techniques.

Available Metal Materials

A wide range of metals can be used in powder form for 3D printing parts, including but not limited to titanium, steel, stainless steel, aluminum, copper, cobalt-chromium alloys, tungsten, and nickel-based alloys. Additionally, precious metals such as gold, platinum, palladium, and silver can also be used for metal 3D printing. Each of these metals has unique properties that make them suitable for various applications.

Types of Metal 3D Printing Technologies

There are two primary types of metal 3D printing technologies: laser-based methods (such as Direct Metal Laser Sintering, DMLS, and Selective Laser Melting, SLM) and Electron Beam Melting (EBM). These technologies create 3D objects by heating and fusing or sintering metal powders together.

Applications of Metal 3D Printing

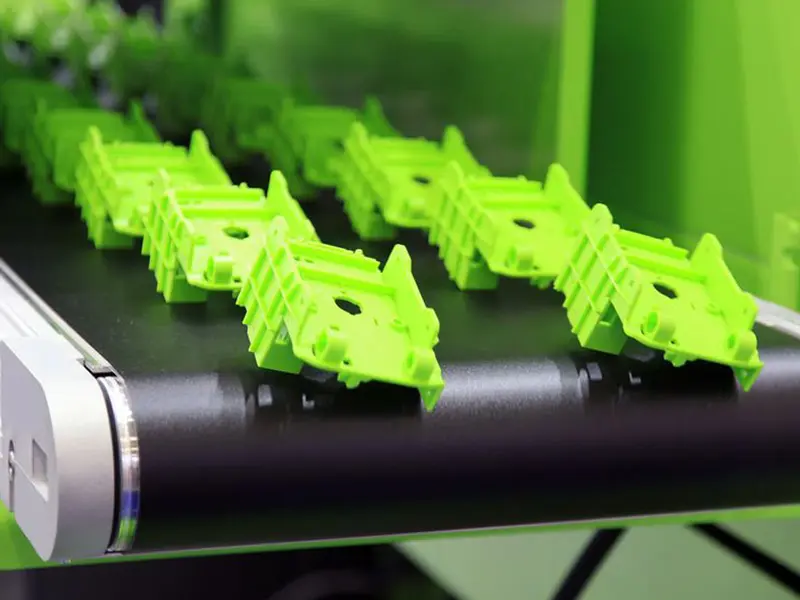

Metal 3D printing technology has found widespread applications in several fields, including:

Aerospace: Used to manufacture high-precision, high-strength components such as jet engine parts.

Automotive: Directly printing automotive engine housings, small accessories, and more, enhancing production efficiency and design freedom.

Medical: Fabricating prosthetics, implants, and other medical devices tailored to individual patients.

Industrial: Widely used in prototype creation, model production, and the production of components for larger assemblies.

Advantages and Disadvantages of Metal 3D Printing

Advantages:

Material Efficiency: Enables precise control over material usage, reducing waste and lowering production costs.

Complex Part Manufacturing: Capable of producing intricate shapes and structures that are difficult or impossible with traditional manufacturing methods.

Customization: Allows for the production of customized products based on individual customer needs.

Lightweighting: Contributes to reducing energy consumption and carbon emissions by enabling the design of lighter components.

Strength and Durability: Metal-printed products offer high strength and durability, suitable for applications requiring robust performance.

Disadvantages:

High Cost: Metal 3D printing equipment and materials are expensive, leading to higher production costs.

Low Production Efficiency: Compared to traditional manufacturing methods, metal 3D printing can have lower production rates.

Post-Processing Required: Metal-printed products often require post-processing (e.g., heat treatment, machining, and surface finishing) to meet usage requirements.

Material Limitations: The range of metals available for metal 3D printing is still limited, constraining its application scope.

Environmental Impact: Metal 3D printing processes can generate waste powder and harmful gases, affecting the environment.

Related searches: Kinds Of 3d Printers Design Of 3d Printer Abs Material In 3d Printing