aluminum 3d printer

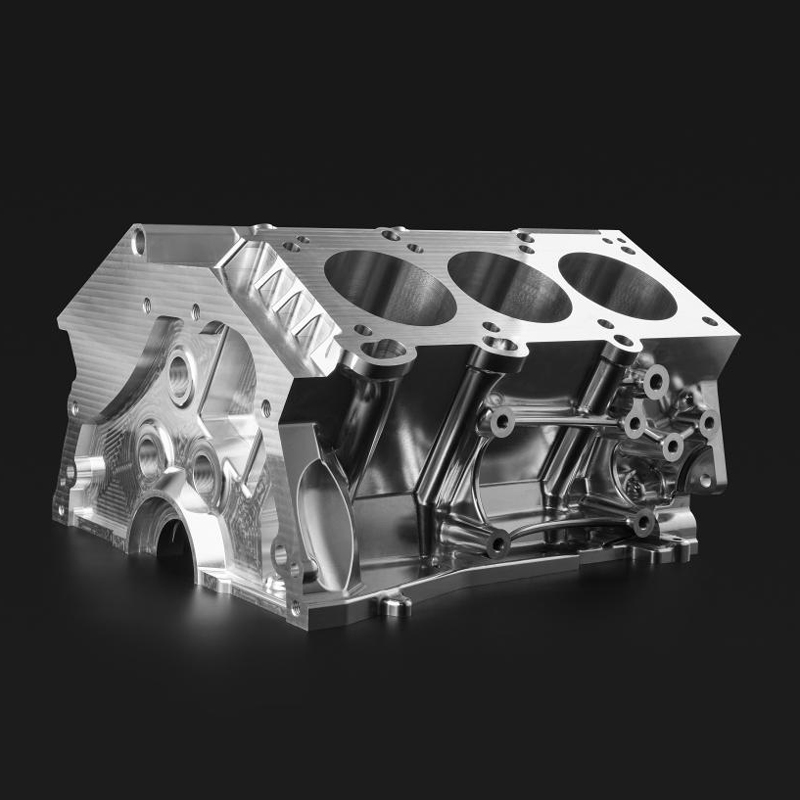

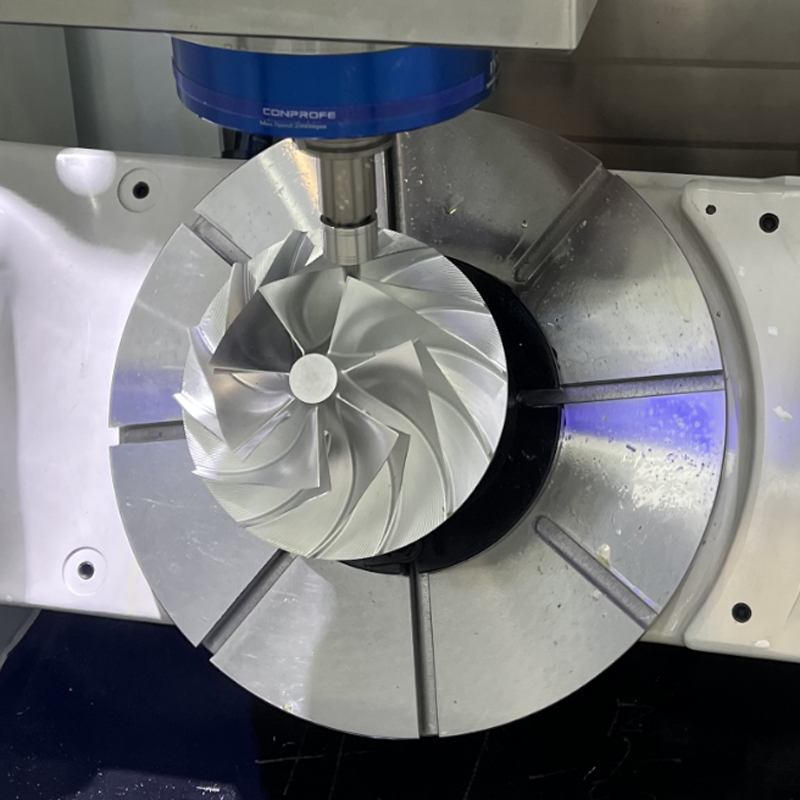

Aluminum 3D printers are a game-changing technology that has revolutionized the way we approach additive manufacturing. These high-end machines are capable of fabricating complex components and structures using aluminum, a lightweight yet strong material that is widely used in various industries. At the core of an aluminum 3D printer is its sophisticated technology, which enables it to transform digital models into tangible objects layer by layer. The process begins with a CAD (Computer-Aided Design) file that contains the detailed specifications of the desired part. This file is then sliced into thin layers using specialized software, providing the printer with a roadmap for construction. The aluminum 3D printer utilizes a powder bed fusion technique, where a fine layer of aluminum powder is evenly distributed on the build platform. A high-power laser or electron beam then selectively melts the powder according to the CAD file's instructions, fusing it into a solid layer. This process is repeated, with each layer building upon the previous one, until the entire part is complete. One of the key benefits of aluminum 3D printing is its ability to create complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. The printer's precision and flexibility allow for the production of intricate internal structures, hollow cavities, and lattice-like infills that optimize strength-to-weight ratio and material usage.