I-Mastering the Craft: Umhlahlandlela ojulile we-CNC Machining kanye nomthelela wawo ekukhiqizeni kwesimanje.

CNC imishini iguqule imboni yokukhiqiza, ivumela ukukhiqizwa okunembayo nangempumelelo kwezingxenye eziyinkimbinkimbi ezimbonini ezihlukahlukene. Le nqubo ihilela ukusetshenziswa kwemishini elawulwa ngekhompiyutha ukusika nokubumba izinto ezingavuthiwe zibe imikhiqizo eqediwe ngokunemba okuyisimangaliso. Kusukela ezimotweni kuya emkhathini, ukwenza imishini ye-CNC kudlala indima ebalulekile ekukhiqizeni izingxenye zekhwalithi ephezulu ezibalulekile kubuchwepheshe besimanje.

Kulo mhlahlandlela ophelele, sizongena emhlabeni wemishini ye-CNC futhi sihlole umthelela wawo ekukhiqizeni kwesimanje. Sizofaka yonke into kusukela kumlando walobu buchwepheshe kuya ekusetshenzisweni kwayo nezinzuzo, kanye nemiqondo eyinhloko, izinqubo, namathuluzi asetshenziswa kumishini ye-CNC. Ekupheleni kwalo mhlahlandlela, uzoba nokuqonda okuphelele kokuthi ukusebenza kwemishini ye-CNC nokuthi kuyiguqule kanjani indlela esenza ngayo imikhiqizo ekhulwini lama-21. Ngakho-ke masingene sijule futhi sibambe kahle ubuciko bemishini ye-CNC ndawonye!

Iyini i-CNC Machining?

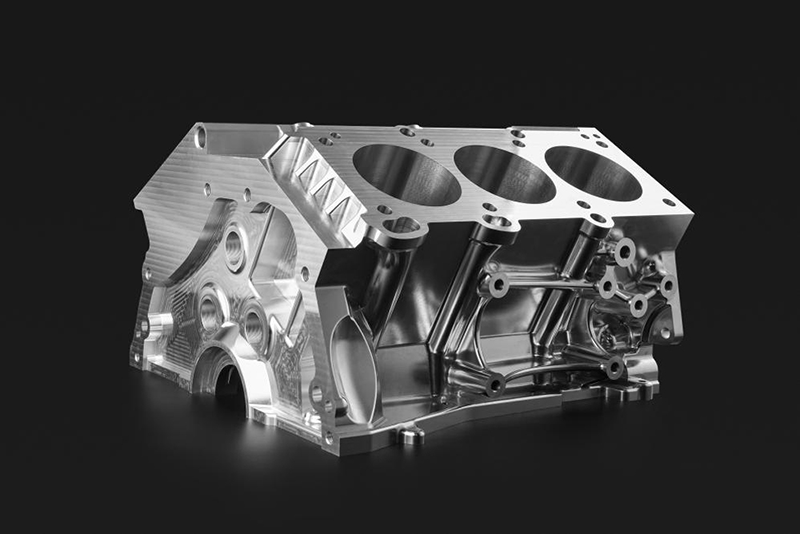

CNC imishini , noma ukwenza imishini ye-Computer Numerical Control, kuyinqubo yokukhiqiza esebenzisa isofthiwe yekhompiyutha namathuluzi omshini ukulawula ukunyakaza kwamathuluzi okusika nokubumba izinto ezingavuthiwe zibe imikhiqizo eqediwe. Sekuyingxenye ebalulekile yokukhiqiza yesimanje ngenxa yekhono layo lokukhiqiza izingxenye ezinembe kakhulu neziyinkimbinkimbi ngesivinini nokusebenza kahle.

Umsuka womshini we-CNC ungalandelelwa emuva kuma-1940s, lapho imishini yokuqala yokulawula izinombolo yathuthukiswa ukuze kusebenze inqubo yokukhiqiza. Kodwa-ke, akuzange kube yiminyaka yawo-1970 lapho ubuchwepheshe bekhompyutha buthuthuke ngokwanele ukwenza ukunyathelisa kwe-CNC kusebenze kahle futhi kufinyeleleke ekusetshenzisweni kwezimboni.

Namuhla, i-CNC machining isetshenziswa ezinhlobonhlobo zezimboni, ezihlanganisa i-aerospace, yezimoto, yezokwelapha, kanye ne-electronics. Kubalulekile ekukhiqizeni izingxenye ezinokubekezelelana okuqinile kanye nemiklamo eyinkimbinkimbi okungeke kwenzeke ukuyifeza ngesandla.

Izinzuzo CNC Machining

Ukusetshenziswa komshini we-CNC kunikeza izinzuzo eziningi kunezindlela zokukhiqiza zendabuko, okwenza kube ukukhetha okudumile ezimbonini zanamuhla. Enye yezinzuzo ezibalulekile yikhono layo lokukhiqiza izingxenye ezinembe kakhulu nezingaguquguquki ezinokubekezelelana okuqinile. Ukunemba komshini we-CNC kuqinisekisa ukuthi ingxenye ngayinye ihlangabezana nokucaciswa okuqondile, kunciphisa ubungozi bamaphutha nokusebenza kabusha.

Enye inzuzo ye-CNC machining ijubane nokusebenza kahle kwayo. Ngokusetshenziswa kwesoftware yekhompiyutha, imiklamo ingaguqulwa ibe imikhiqizo eqediwe engxenyeni yesikhathi ebingasithatha kusetshenziswa izindlela zendabuko. Lokhu kuvumela ukukhiqizwa okusheshayo kanye nezikhathi zokuhola ezimfushane, okuyinto ebalulekile emakethe yanamuhla esheshayo.

CNC imishini futhi ivumela ukwanda kokuguquguquka nokuguquguquka. Umshini ofanayo ungase usetshenziselwe ukukhiqiza izingxenye eziningi, ngokushintsha iziqondiso ohlelweni lwe-computer. Lokhu kuyenza ilungele ukukhiqizwa kweqoqo elincane nama-oda enziwe ngokwezifiso.

Ngaphezu kwalezi zinzuzo, imishini ye-CNC iphinde inikeze ukuphepha okuthuthukisiwe nokusebenza kahle kwezindleko. Ngezinqubo ezizenzakalelayo, kunengozi encane yezingozi nokulimala kwabasebenzi. Futhi ngokuncipha kokuqashwa kwabantu, izindleko zokukhiqiza zingehliswa kakhulu, okuholela ekongeni kwezindleko zamabhizinisi.

Umhlahlandlela we-CNC Machining Izinqubo namathuluzi

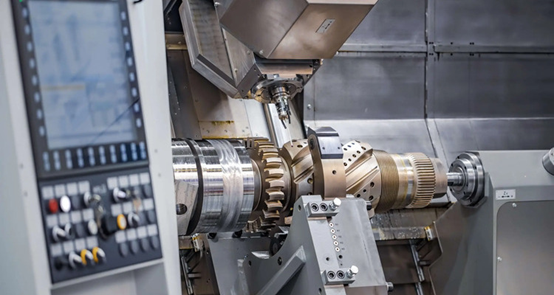

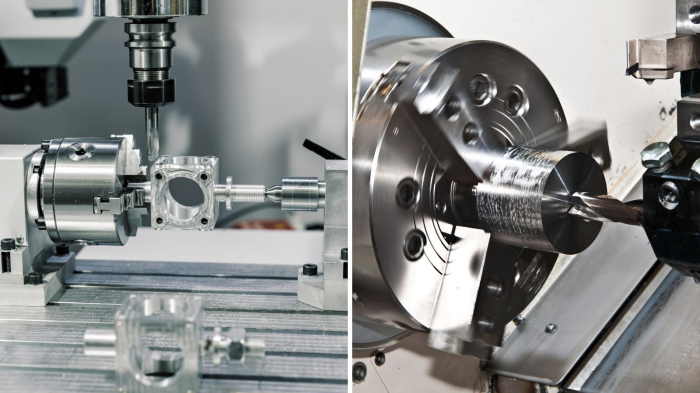

I-CNC machining ihlanganisa izinqubo namathuluzi ahlukahlukene asebenza ndawonye ukuze alolonge izinto ezingavuthiwe zibe imikhiqizo eqediwe. Izinqubo ezivame kakhulu zihlanganisa ukugaya, ukuphenduka, ukubhoboza, nokugaya.

Ukugaywa kuyinqubo yokusebenzisa abasiki be-rotary ukuze basuse izinto ezibonakalayo kucezu lokusebenza, okwenza umumo noma umklamo oyifunayo. Ukujika, ngakolunye uhlangothi, kuhilela ukuzungezisa ucezu lokusebenza kuyilapho ithuluzi lokusika lihamba lihambisana ne-eksisi yalo, okuholela ezingxenyeni eziyisilinda.

Ukubhoboza kungenye inqubo ebalulekile kumishini ye-CNC, esebenzisa izingcezu zokubhoboza ezizungezayo ukudala izimbobo endaweni yokusebenza. Futhi ukugaya kusetshenziselwa ukuqedela ukunemba kwezindawo ngokususa inani elincane lezinto ngesondo eliqhumayo.

Ngaphezu kwalezi zinqubo, kukhona amathuluzi ahlukahlukene asetshenziswa kuCNC imishini , njengezinsimbi, izigayo, izimbobo, nezigayo. Lawa mathuluzi angalawulwa uhlelo lwekhompiyutha ukuze asike kahle futhi alolonge izinto ngokuya ngemininingwane yokuklama.

Kuyafaneleka futhi ukusho ukuthi intuthuko kwezobuchwepheshe iholele ekuthuthukisweni kwemishini ye-multi-axis, evumela imiklamo eyinkimbinkimbi futhi eyinkimbinkimbi. Le mishini inganyakazisa ithuluzi lokusika lihambisane nezimbazo eziningi ngesikhathi esisodwa, okuholela ekukhiqizeni okusheshayo nokunembe kakhudlwana.

Futhi, ukusetshenziswa kwesofthiwe ekhethekile kanye nemiklamo ye-CAD/CAM yenze imishini ye-CNC yasebenza kahle futhi inembe kakhudlwana. Lezi zinhlelo zivumela ukumodela kwe-3D nokulingisa, okuqinisekisa ukuthi umkhiqizo wokugcina uhlangabezana nazo zonke izidingo zokuklama ngaphambi kokuthi wenziwe.

Umthelela we-CNC Machining Ekwenziweni Kwesimanje

Akukho ukuphika lokhoCNC imishini ibe nomthelela omkhulu ekukhiqizeni kwesimanje. Ikhono layo lokukhiqiza izingxenye ezinembe kakhulu neziyinkimbinkimbi engxenyeni yesikhathi liguqule indlela esiklama ngayo, esithuthukisa ngayo, futhi sikhiqize imikhiqizo ezimbonini ezihlukahlukene. Nazi ezinye zezindlela ezibalulekile ze-CNC machining ezibe nomthelela ekwenzeni:

Okuzenzakalelayo

Okuzenzakalelayo kungomunye wemithelela ebaluleke kakhulu yeCNC imishini ekukhiqizeni kwesimanje. Ngokusetshenziswa kwesoftware yekhompiyutha nezinqubo ezizenzakalelayo, umsebenzi womuntu uyancishiswa, okuholela ekwandeni kokusebenza kahle nokukhiqiza. Lokhu kuphinde kwaholela ekwehleni kwamaphutha nokusebenza kabusha, okuholele emikhiqizweni yekhwalithi ephezulu.

Futhi, ukuzenzekelayo kwezinqubo kwenze ukuba imishini ye-CNC ifinyeleleke ezinhlobonhlobo ezibanzi zezimboni namabhizinisi. Ayisadingi opharetha abanamakhono aphezulu ukuthi basebenzise imishini mathupha, okwenza ukuthi kungabizi kakhulu futhi kusebenze kahle ezinkampanini ezincane ukuzisebenzisa.

Ukwengeza, ukusetshenziswa kwe-automation kuye kwathuthukisa ukuphepha ezindaweni zokukhiqiza. Ngokuphathwa kwezandla okuncane nemisebenzi edinga abasebenzi abaningi, kunengozi enciphile yezingozi nokulimala kwabasebenzi.

Ukukhiqiza Nokuphumelela Kwandisiwe

Imishini ye-CNC ikhulise kakhulu ukukhiqiza nokusebenza kahle ekukhiqizeni kwesimanje. Izindlela zendabuko zivame ukubandakanya izinqubo ezidla isikhathi ezidinga abasebenzi abanamakhono ukuthi basebenzise imishini ngesandla, okuholela ezikhathini ezinde zokukhiqiza. Ngomshini we-CNC, izinqubo ezifanayo zingazenzakalela futhi ziqedwe ngokushesha okukhulu, zinciphise izikhathi zokuhola futhi zivumele ukukhiqizwa okwengeziwe ngesikhathi esifushane.

Ngaphezu kwalokho, ngemishini elawulwa ngekhompiyutha esebenza ubusuku nemini, asikho isidingo sokuphumula noma ukuphumula. Lokhu kusho ukuthi ukukhiqiza kungaqhubeka ngaphandle kokuphazamiseka, okuholela ekwenyukeni kokusebenza kahle kanye nokuphumayo.

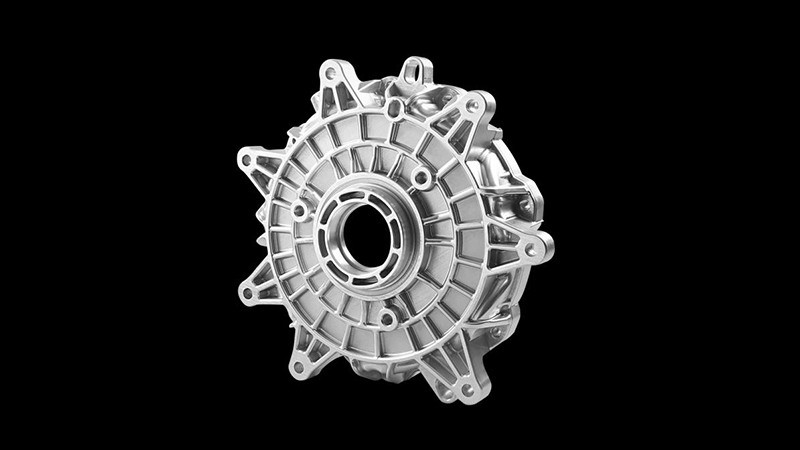

Ukunemba Okuthuthukisiwe Nokunemba

Ukunemba nokunemba yizici ezibalulekile ekukhiqizeni, njengoba ngisho nephutha elincane lingaholela ezingxenyeni ezinesici noma ukwehluleka komkhiqizo. Imishini ye-CNC iguqule ukunemba nokunemba ngokusebenzisa izinqubo ezilawulwa ngekhompuyutha ezilandela ukucaciswa okuqondile kwedizayini.

Ngokungafani nezindlela ezenziwa ngesandla, ezithambekele ekwenzeni iphutha lomuntu,Imishini ye-CNC ingahlala ikhiqiza izingxenye ezinembe kakhulu ezinokubekezelelana okuqinile. Lokhu akugcini nje ngokuholela emikhiqizweni yekhwalithi ephezulu kodwa futhi kunciphisa isidingo sokusebenza kabusha, ukonga isikhathi nezindleko zamabhizinisi.

Ukwengeza, imishini ye-CNC ingakhiqiza imiklamo eyinkimbinkimbi neyinkimbinkimbi engenakwenzeka noma enzima kakhulu ukuyifeza ngesandla. Lokhu kuvula amathuba okuqamba izinto ezintsha nokudala ekwakhiweni komkhiqizo.

Izikhathi zokukhiqiza ezisheshayo

Njengoba kushiwo ngaphambili, ukwenza imishini ye-CNC kunciphise kakhulu izikhathi zokukhiqiza uma kuqhathaniswa nezindlela zendabuko. Ngokusetshenziswa kwezinqubo ezizenzakalelayo kanye nesofthiwe ethuthukisiwe, izingxenye zingakhiqizwa ngesivinini esisheshayo ngokungenelela okuncane komuntu.

Lokhu kuvumela amabhizinisi ukuthi ahlangabezane neminqamulajuqu eqinile futhi agcwalise ama-oda ngokushesha, okuholela ekwandiseni ukwaneliseka kwamakhasimende nokugcinwa. Iphinde inikeze izinkampani ithuba lokuncintisana ngokukwazi ukuletha imikhiqizo emakethe ngokushesha.

Izindleko Ezehlisiwe Zabasebenzi

Izindleko zomsebenzi zingaba yizindleko ezinkulu kumabhizinisi, ikakhulukazi uma kuziwa emsebenzini wezandla odinga amakhono akhethekile. Imishini ye-CNC yehlise izindleko zabasebenzi ngokwenza izinqubo kanye nokunciphisa isidingo sabasebenzi abanamakhono aphezulu.

Ngaphezu kwalokho, ngezikhathi zokukhiqiza ezisheshayo, kudingeka abasebenzi abambalwa ukuze baqedele inani elifanayo lomsebenzi, okuqhubeka nokunciphisa izindleko zabasebenzi. Lokhu kwenza ukwenza i-CNC kube inketho engabizi kakhulu kumabhizinisi, ikakhulukazi amancane anezinsiza ezilinganiselwe.

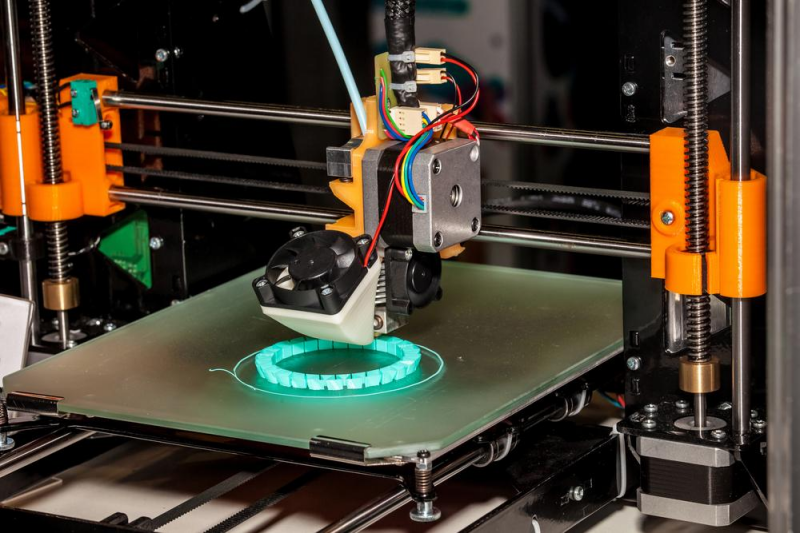

Ukuguquguquka Nokuguquguquka Ekukhiqizeni

Enye yezinzuzo ezinkulu zeCNC imishini ukuguquguquka kwayo kanye nokuguquguquka ekukhiqizeni. Ngokusetshenziswa kwamathuluzi ahlukene kanye nemishini ye-multi-axis, izinhlobonhlobo zemiklamo kanye nezinto zokwakha zingamukeleka. Lokhu kuvumela uhla oluhlukahlukene lwemikhiqizo ukuthi lukhiqizwe kusetshenziswa imishini ye-CNC, okuyenza ifanele izimboni ezihlukahlukene ezifana ne-aerospace, ezezimoto, nezokwelapha.

Ngaphezu kwalokho, ngekhono lokushintsha ngokushesha phakathi kwemiklamo futhi kukhiqizwe izingxenye ezenziwe ngokwezifiso, ukwenziwa kwemishini ye-CNC kunikeza ukuguquguquka ekukhiqizeni izindlela zendabuko ezingenakufana. Lokhu kunenzuzo ikakhulukazi kumabhizinisi adinga ukukhiqizwa kwenqwaba encane noma avame ukushintsha imiklamo.

Futhi, ukusetshenziswa kwesoftware ye-CAD/CAM kuvumela ukuthi kube noshintsho olulula ekwenziweni kwemiklamo, kuqinisekiswe ukuthi umkhiqizo wokugcina uhlangabezana nazo zonke izidingo kanye nokucaciswa. Lokhu akugcini nje ngokusindisa isikhathi kodwa kunciphisa nokumosha nezindleko.