I-CNC Lathe vs CNC Turning Center: Umehluko Wohlelo Lokusebenza

Umshini weComputer Numerical Control (CNC) uguqule imboni yokukhiqiza, uhlinzeka ngokukhiqiza okunembayo nangempumelelo kwezingxenye ezihlukahlukene. Izinhlobo ezimbili ezivame ukusetshenziswa kakhulu zemishini ye-CNC yizintambo kanye nezikhungo zokuphendula. Nakuba zombili zenzelwe ukukhanda izingxenye ze-cylindrical, zinokuhluka kwazo ngokuya ngesicelo.

I-CNC lathe iyithuluzi lomshini elizungezisa ucezu lokusebenza ku-eksisi yalo ukwenza imisebenzi efana nokusika, ukubhoboza, ukuknurling, nokufaka isihlabathi. Ngakolunye uhlangothi, isikhungo sokujika se-CNC siwuhlobo oluthuthukisiwe lwelathe elinezici ezengeziwe ezifana namakhono okugaya, ukusebenzisa amathuluzi abukhoma, nezinsimbi zokuphotha zesibili.

Kulesi sihloko, sizoxoxa ngomehluko phakathi kwe-CNC lathe kanye nesikhungo sokuguqula i-CNC mayelana nesicelo, ukukusiza ukuthi uqonde ukuthi yimuphi umshini ofaneleka kakhulu izidingo zakho zokukhiqiza.

Iyini i-CNC Lathe?

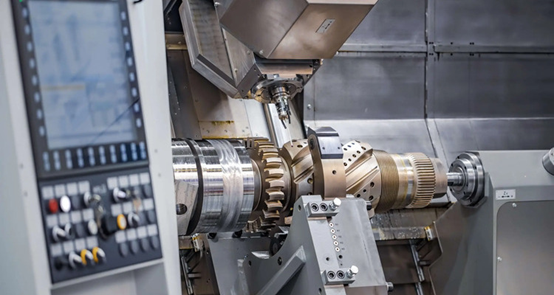

AI-CNC lathe iyithuluzi lomshini elizungezisa ucezu lokusebenza ku-eksisi yalo ukuze lenze imisebenzi ehlukahlukene njengokusika, ukubhoboza, ukuknurling, nokufaka isihlabathi. Isebenzisa izilawuli zekhompuyutha ukuhumusha iziqondiso ezihleliwe zibe imiyalo yokunyakaza yomshini. I-lathe iqukethe izingxenye ezimbili eziyinhloko- i-headstock kanye nenqola. I-headstock iqukethe i-spindle eyinhloko ebamba futhi ijikeleze ucezu lokusebenza, kuyilapho inqola ihamba ngobude bemigwaqo yokulala ukuze ilawule amathuluzi okusika.

Amalebula e-CNC asetshenziselwa ngokuyinhloko ukwenza izingxenye ezimise okwesilinda noma eziyisiyingi ngokunemba okuphezulu nokunemba. Angasetshenziswa futhi ekubhekeni, ekugwebeni, ekuthungeni nasekusebenzeni okuyisicefe. Ngekhono labo lokuphindaphinda ukusikeka okuyinkimbinkimbi ngokuphindaphindiwe, le mishini ilungele ukukhiqizwa kwevolumu ephezulu yezingxenye ezilula.

Izintambo ze-CNC zitholakala ngosayizi abahlukahlukene, kusukela kumamodeli amancane edeskithophu kuya emishinini emikhulu yezimboni ekwazi ukuphatha umsebenzi osindayo. Avame ukusetshenziswa ezimbonini zezimoto, ze-aerospace, kanye nezokwelapha ekwenzeni izinto ezifana namashafti, ama-pistons, nama-valve.

Yini i-CNC Turning Center?

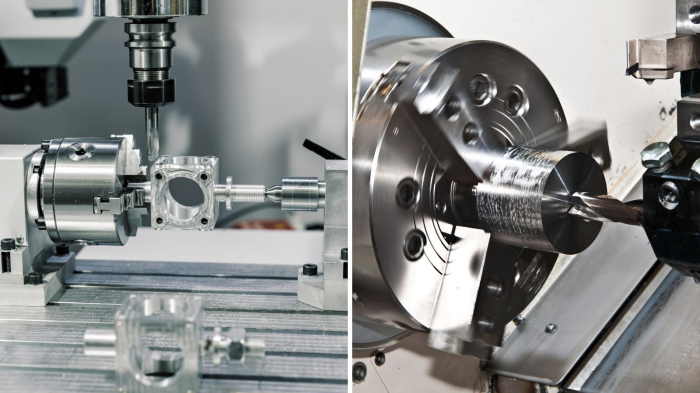

AIsikhungo sokujika se-CNC inguqulo ethuthukisiwe ye-lathe enezici ezengeziwe ezifana namakhono okugaya, ukusebenzisa amathuluzi abukhoma, nama-spindles esibili. Ihlanganisa imisebenzi ye-lathe kanye nesikhungo somshini emshinini owodwa, ihlinzeka ngokuguquguquka okukhulu nokusebenza kahle ekukhiqizeni.

Isikhungo sokujika sinento yokuphotha eyinhloko yokuzungezisa isiqeshana sokusebenza kanye nesesibili sokuphotha sokwenza imisebenzi efana nokugaya, ukubhola, ukucofa kanye nokubhoboza ngaphandle kwendawo. Lokhu kuqeda isidingo sokudlulisa i-workpiece phakathi kwemishini ehlukene, ukonga isikhathi nokunciphisa amaphutha.

Izikhungo zokuguqula i-CNC zivame ukusetshenziselwa imisebenzi yemishini eyinkimbinkimbi futhi enemisebenzi eminingi. Angakwazi ukukhiqiza umumo nezici eziyinkimbinkimbi kuzo zombili iziphetho zengxenye ngesikhathi esisodwa, okuzenza zilungele ukukhiqiza izingxenye ezifana namagiya, shafts ezinokhiye noma ama-splines, kanye nezingxenye zezokwelapha eziyinkimbinkimbi.

Ngokungeziwe emandleni azo athuthukile, izikhungo eziphendukayo ziphinde zinikeze izikhathi zomjikelezo osheshayo nokunemba okuphezulu uma kuqhathaniswa namalebula e-CNC. Zisetshenziswa kakhulu ezimbonini ezifana ne-aerospace, ukuzivikela, kanye nowoyela negesi ukuze bakwazi ukukhiqiza izingxenye eziyinkimbinkimbi ezinokubekezelelana okuqinile.

Ukwahlukana Okuyinhloko phakathi kwe-CNC Lathe ne-CNC Turning Center

Banguumehluko omkhulu phakathi kwe-CNC lathe kanye nokujika kwe-CNCisikhungo, okubenza bafanelekele izinhlelo zokusebenza ezahlukene.

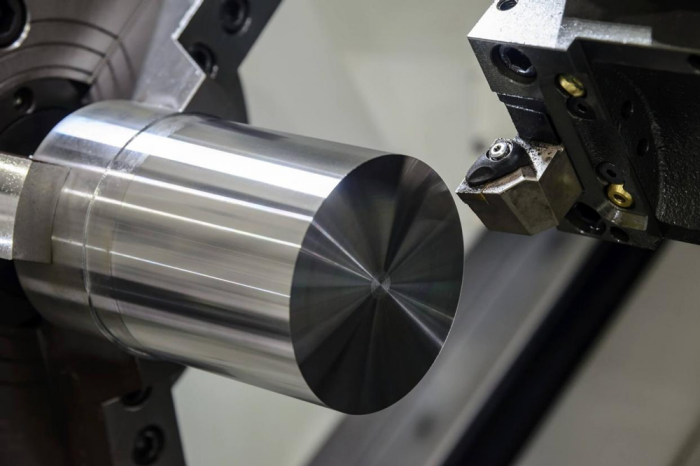

Idizayini

Idizayini ye-CNC lathe kanye nesikhungo sokuphendula se-CNC siyahluka kakhulu, okunomthelela ekusetshenzisweni kwazo okuhlosiwe kanye namandla. Ilathe ye-CNC ngokuvamile ilula ekwakhiweni futhi ngokuyinhloko igxile ekuguquleni imisebenzi lapho ucezu lomsebenzi luzungeza kuyilapho ithuluzi lokusika lihlala limile. Ihlanganisa i-spindle eyinhloko, i-headstock, nesistimu yenqola elula ukuze kube lula ukunyakaza okuqondile.

Ngakolunye uhlangothi, isikhungo sokuguqula i-CNC siyinkimbinkimbi ekwakhiweni futhi sihlanganisa imisebenzi eminingi ngale kokuphenduka nje. Kubandakanya ukuphotha okungeziwe, ukwenza amathuluzi abukhoma, futhi kuvame ukufaka i-Y-eksisi, eyinika amandla okwenza imisebenzi yokugaya, ukubhola, nokuthepha ngaphakathi kokusetha okufanayo. Lo mklamo onemisebenzi eminingi uvumela isikhungo sokujika ukuthi siphathe imisebenzi yomshini eyinkimbinkimbi futhi enezici eziningi ngaphandle kwesidingo sokudlulisa isiqeshana somsebenzi emshinini ohlukile.

Lo mehluko wokuklama wenza ama-lathe e-CNC alungele imisebenzi yokukhiqiza eqondile, enevolumu ephezulu kuyilapho izikhungo zokuguqula i-CNC zifaneleka kangcono izidingo zokukhiqiza eziyinkimbinkimbi, ezinezinqubo eziningi.

Imisebenzi

Omunye umehluko obalulekile phakathi kwe-CNC lathe kanye nesikhungo sokujika se-CNC ububanzi bemisebenzi abangayenza. Njengoba kushiwo ngaphambili, i-lathe ngokuyinhloko igxile ekuguquleni imisebenzi efana nokubheka, ukugoba, ukubhoboza, ukuthunga, kanye nokubhora. Le mishini ilungele ukukhiqiza izingxenye ezilula ze-cylindrical noma ze-conical ngokunemba okuphezulu.

Ngaleso sikhathi, isikhungo sokujika sinikeza ukuguquguquka okuthuthukile nekhono laso lokusingatha izinqubo eziningi ngesikhathi esisodwa. Ingenza imisebenzi eyahlukene yokugaya njengokugaya ubuso, ukuqeda ukugaywa, kanye nokubhola kusetshenziswa izinto ezisetshenziswa bukhoma kuyilapho ukuphotha okuyinhloko kuzungezisa ucezu lokusebenza. Leli khono elithuthukisiwe livumela amajiyometri ayinkimbinkimbi kakhulu ukuthi enziwe ngomshini ngokuphumelelayo ekusetheni okukodwa.

Ngenkathi yomibili le mishini yabelana ngemisebenzi ethile evamile eyisisekelo njengokunyakaza komugqa nokuzungezayo, uhla lwayo lokusebenza luyayihlukanisa futhi yenze eyodwa ifaneleke kakhulu izinhlelo ezithile kunomunye.

Ukuvumelana nezimo

Ukuvumelana nezimo ngomunye umehluko obalulekile phakathi kwe-CNC lathe kanye nesikhungo sokuphendula se-CNC. I-lathe yakhelwe ukuphatha ukukhiqizwa kwevolumu ephezulu yezingxenye ezilula ezinokuhlukahluka okuncane ekuklanyweni. Ingakhiqiza ngempumelelo izingxenye eziningi ezifanayo, iyenze ilungele ukukhiqizwa ngobuningi.

Ngakolunye uhlangothi, aisikhungo sokuphenduka inikeza ukuguquguquka okukhulu njengoba ingamukela imiklamo ehlukahlukene nezinto zokwakha ngaphandle kokudinga ukulungiswa kabusha okubanzi noma izinguquko zokusetha. Amandla ayo okwenza imisebenzi eminingi ayenza ikwazi ukubhekana nezingxenye eziyinkimbinkimbi ezinezici ezihlukahlukene namajiyometriki ekusetheni okukodwa ngokushesha, inciphise isikhathi sokukhiqiza nezindleko.

Ukuvumelana nezimo okunikezwa isikhungo sokujika kuyenza ifaneleke kakhulu ukukhiqizwa kwevolumu ephansi kuya emaphakathi yezingxenye ezingokwezifiso, ikakhulukazi ezimbonini ezifana ne-aerospace kanye nezokwelapha lapho izingxenye zemiklamo zishintsha njalo.

Inkimbinkimbi

Mayelana nobunkimbinkimbi, isikhungo sokujika se-CNC ngokungangabazeki sithuthuke kakhulu kune-lathe. Idizayini yayo ihlanganisa ama-spindle amaningi, amathuluzi abukhoma, kanye ne-Y-axis, okuyenza ikwazi ukuphatha imisebenzi ehlukahlukene ngesikhathi esisodwa. Lokhu kwandisa inkimbinkimbi yayo yonke kodwa futhi kunikeza ukuguquguquka okukhulu nokusebenza kahle ekukhiqizeni.

I-lathe, ngakolunye uhlangothi, inomklamo olula onezingxenye ezimbalwa ezihambayo nokusebenza. Lokhu kwenza kube lula ukusebenza nokuyinakekela kodwa kukhawulela amandla ayo uma kuqhathaniswa nesikhungo sokujika.

Ngokuya ngezidingo zenqubo yokukhiqiza, noma yimuphi umshini ungakhethwa. Ezingxenyeni ezilula ezinomsebenzi omncane, i-lathe ingase yanele. Kodwa-ke, ngezingxenye eziyinkimbinkimbi ezidinga izinqubo eziningi, isikhungo sokujika sinikeza amakhono adingekayo.

Umthamo Wokukhiqiza

Umehluko owodwa wokugcina phakathi kwe-CNC lathe kanye nesikhungo sokuphendula se-CNC amandla abo omthamo wokukhiqiza. Njengoba kushiwo ngaphambili, ama-lathes ngokuvamile asetshenziselwa ukukhiqizwa kwevolumu ephezulu yezingxenye ezifanayo. Idizayini yabo elula ivumela ukukhiqizwa okusheshayo kanye nezikhathi zomjikelezo, okubenza balungele ukukhiqizwa ngobuningi.

Ngokolunye uhlangothi,turning izikhungo kukhona ifaneleka kangcono ukukhiqizwa kwevolumu ephansi ukuya emaphakathi ngenxa yamakhono abo athuthukile kanye nekhono lokuphatha imiklamo ehlukahlukene nezinto zokwakha ngempumelelo. Baphinde banikeze izikhathi ezimfushane zokusetha uma kuqhathaniswa nezikhungo zemishini zendabuko, ezizenza zifanelekele ukukhiqizwa kweqoqo elincane elishintshashintsha njalo.

Ngakho-ke lena umehluko omkhulu phakathi kwe-CNC lathe kanye nesikhungo sokuphendula se-CNC. Nakuba zingase zibonakale zifana ekuqaleni, ukuklama kwazo, ukusebenza, ukuguquguquka, ukuba yinkimbinkimbi, namandla omthamo wokukhiqiza kuzihlukanisa futhi kuzenze zifaneleke kangcono izidingo zokukhiqiza ezihlukene. Ukuqonda lo mehluko kungasiza abakhiqizi bakhethe umshini ofaneleka kakhulu ukuhlangabezana nezidingo zabo ezithile futhi bathuthukise izinqubo zabo zokukhiqiza.

Ungakhetha Kanjani Phakathi Kwelathe ye-CNC kanye Nesikhungo Sokuguqula I-CNC

Lapho sinqumaphakathi kwe-CNC lathe kanye nesikhungo sokujika se-CNC , izici eziningana okudingeka zicatshangelwe. Okokuqala, uhlobo lwengxenye noma ingxenye ekhiqizwayo idlala indima ebalulekile. Ezingxenyeni ezilula ze-cylindrical noma ze-conical ezinomthamo ophezulu wokukhiqiza, i-lathe ingaba yisinqumo esingcono kakhulu ngenxa yokusebenza kahle kwayo kanye nezindleko eziphansi.

Ngakolunye uhlangothi, ezinxenyeni eziyinkimbinkimbi kakhulu ezidinga izinqubo eziningi ezinamavolumu aphansi ukuya kwaphakathi, isikhungo esiguqukayo singanikeza ukuguquguquka okukhulu nokuguquguquka.

Isabelomali singesinye isici esibalulekile lapho ukhetha phakathi kwale mishini. Amalebula ngokuvamile awabizi kakhulu kunezikhungo zokujika ngenxa yokwakheka kwawo okulula nokusebenza okumbalwa. Ngakho-ke, uma izinkinga zesabelomali ziyinkinga, i-lathe ingase ibe inketho esebenzayo.

Ukwengeza, kubalulekile ukucabangela indawo etholakalayo endaweni yokukhiqiza. Izikhungo eziphendukayo zidinga indawo engaphezulu ngenxa yosayizi wazo omkhulu kanye nezingxenye ezengeziwe ezifana namathuluzi abukhoma nama-spindle amaningi. Uma kuqhathaniswa, ama-lathes mancane futhi athatha indawo encane.

Ekugcineni, abakhiqizi kufanele bahlole ngokucophelela izidingo zabo zokukhiqiza futhi bazikale ngokuqhathanisa namandla kanye nemikhawulo yomshini ngamunye ngaphambi kokwenza isinqumo. Ukubonisana nochwepheshe nokwenza ucwaningo olunzulu nakho kungasiza ekukhetheni umshini ofaneleka kakhulu ukuze usebenze kahle futhi wenze inzuzo.

Ingabe Inhlanganisela Yayo Yomibili Imishini Ikhona?

Yebo,imishini yokuhlanganisa ahlanganisa kokubili amandla esikhungo se-lathe kanye nesikhungo sokujika akhona. Le mishini eyingxubevange inikeza okungcono kakhulu kuyo yomibili imihlaba, enekhono lokwenza imisebenzi ehlukahlukene yokujika kuyilapho inamandla okugaya nokumba.

Idizayini eyingxube ivumela ukuguquguquka okwengeziwe nokusebenza kahle ekukhiqizeni njengoba iqeda isidingo sokusetha okuningi futhi inciphisa izikhathi zomjikelezo. Iphinde yonga isikhala endaweni yokukhiqiza ngokuhlanganisa imishini emibili ibe munye.

Kodwa-ke, le mishini ehlanganisiwe ingase ingafaneleki kuzo zonke izinhlobo zemikhiqizo njengoba ivame ukuba nemikhawulo ngokobukhulu nobunkimbinkimbi uma iqhathaniswa nezintambo ezizimele noma izikhungo zokujika.

Abakhiqizi kufanele bahlole ngokucophelela izidingo zabo zokukhiqiza ngaphambi kokutshala imali emshinini oyingxubevange ukuze baqinisekise ukuthi ukwazi ukuphatha izidingo zabo ngendlela efanele. Kufanele futhi bacabangele izindleko ezingaba khona zokunakekela kanye nokusebenza komshini oyinhlanganisela uma kuqhathaniswa nokuba nemishini ehlukene yokusebenza ngakunye.

Futhi, njengoba ubuchwepheshe buqhubeka nokuthuthuka, imishini ye-hybrid iba yinkimbinkimbi futhi ikwazi ukuphatha imisebenzi eyinkimbinkimbi. Ngakho-ke, kubalulekile ukuthi uhlale unolwazi ngentuthuko yakamuva kule ndawo ukuze unqume ukuthi umshini ohlanganisayo uzoba utshalomali olufanele yini enqubweni yakho yokukhiqiza.

Amaphutha Okufanele Uwagweme Lapho Ukhetha Phakathi Kwe-CNC Lathe kanye Nesikhungo Sokuguqula I-CNC

Lapho unquma phakathi kwe-CNC lathe kanye nesikhungo sokujika se-CNC, kukhona amaphutha avamile okumele abakhiqizi bawagweme. Nazi ezinye zazo:

- Ukukhetha ngokusekelwe kwintengo kuphela : Nakuba isabelomali siwukucatshangelwa okubalulekile, akufanele kube yiyona kuphela into ekuthathweni kwezinqumo. Umshini oshibhile ungase ugcine ubiza kakhulu ngokwezindleko zokunakekela kanye nokusebenza uma ungakwazi ukubhekana nezimfuneko zokukhiqiza.

- Ukudebesela ukuhlola izidingo zokukhiqiza : Kubalulekile ukuhlola ngokucophelela izingxenye ezithile ezikhiqizwayo kanye nokusebenza kwazo okudingekayo ngaphambi kokukhetha umshini. Ukwehluleka ukwenza kanjalo kungaholela ekukhetheni umshini onganele ongahlangabezani nazo zonke izidingo zokukhiqiza.

- Singacabangi ukukhula kwesikhathi esizayo : Lapho utshala imali emshinini we-CNC, abakhiqizi kufanele bacabangele nezinhlelo zabo zokukhula zesikhathi esizayo. Ingabe bazodinga umshini omkhulu noma othuthuke kakhulu phansi komugqa? Lokhu kungabasindisa ekutheni bashintshe noma bathuthukise okokusebenza kwabo ngokushesha kunokulindelekile.

- Ukuziba izindleko zesondlo nezokusebenza : Njengoba kushiwo ngaphambili, intengo yokuqala yomshini akufanele kube ukuphela kwezindleko ezicatshangelwayo. Abakhiqizi kufanele futhi bacabangele izindleko zokunakekela nezokusebenza ukuze banqume ukonga izindleko komshini.

Ngokugwema la maphutha, abakhiqizi bangakwazi ukuhlola kangcono izinketho zabo futhi bakhethe umshini ofaneleka kakhulu ngezidingo zabo zokukhiqiza, okuholela ekwandeni kokusebenza kahle kanye nenzuzo.

Xhumana ne-Breton Precision Ukuze Uguqule I-CNC Yakho Nezinye Izidingo Zokukhiqiza

I-Breton Precision iyisitolo sakho esisodwa sakho konkeIzidingo ze-CNC Lathe kanye ne-CNC turning centre . Ngobuchwepheshe bethu obuthuthukile nezingcweti ezinekhono, singakunikeza izingxenye eziphendulwe zekhwalithi ephezulu kumaphrojekthi akho ahlukile. Sinikeza ububanzi beamasevisi kuhlanganiseukujika kwe-CNC ocingweni, izikhathi zokuhola ngokushesha, kanye nokwesekwa kobunjiniyela okungu-24/7 ukuqinisekisa izinga eliphezulu lokwaneliseka kwamakhasimende.

Inkampani yethu izibophezele ekuletheni izingxenye eziphendulwe zekhwalithi ephezulu ngokunemba nokusebenza kahle. Sinohlelo oluqinile lokulawula ikhwalithi ukuze siqinisekise ukuthi yonke imikhiqizo yethu ihlangabezana nezindinganiso ezilindelekile futhi ayinazo iziphambeko.

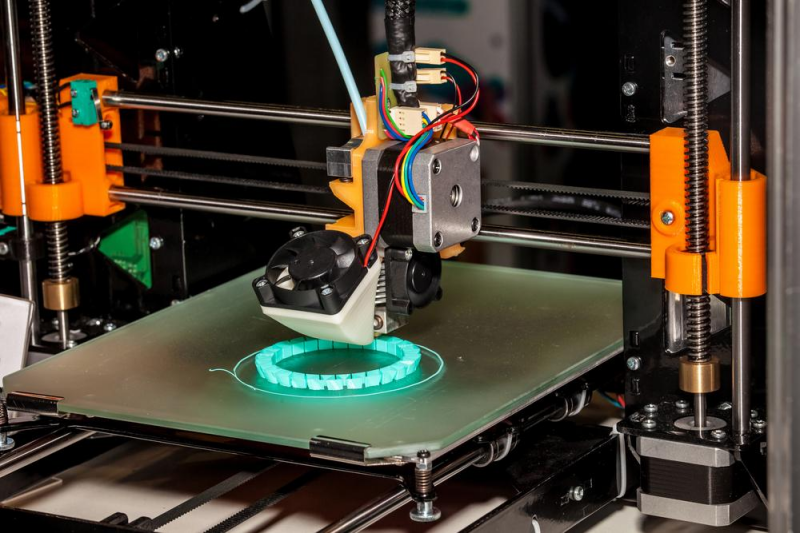

Ngemishini yethu yesimanje kanye nezinsiza, sisebenza ngokukhethekileCNC imishini,ukubumba umjovo wepulasitiki,ukwenziwa kweshidi lensimbi,ukukhishwa kwe-vacuum, futhiUkuphrinta kwe-3D . Ithimba lethu lochwepheshe lingakwazi ukuphatha amaphrojekthi asukela ekukhiqizeni okuyisibonelo kuya ekukhiqizeni ngobuningi kalula. Siphinde sinikeleamanani okuncintisanakanye nezikhathi zokuhola ngokushesha, uqinisekisa ukuthi amaphrojekthi akho aqedwa ngesikhathi nangendlela eyongayo.

NgoI-Breton Precision , siyakuqonda ukubaluleka kokunemba nokunemba ekukhiqizeni. Kungakho silwela ukufinyelela ukubekezelela okuphansi okungafika ku-±0.005” ezinsimbi ezigayiwe, sihlangabezana namazinga e-ISO kukho kokubili amapulasitiki nezinsimbi.

Xhumana nathi kuinfo@breton-precision.com noma usishayele ku-0086 0755-23286835 ngakho konke ukujika kwe-CNC yakho nezinye izidingo zokukhiqiza. Ithimba lethu lochwepheshe abazinikele liyatholakala 24/7 ukuze likunikeze izixazululo ezingcono kakhulu zokuklama, ukukhetha izinto zokwakha, nokuphatha izikhathi zokuhola. Ake sikusizeletha amaphrojekthi akhoukuze siphile ngezinkonzo zethu zokuphendula ze-CNC ezisezingeni eliphezulu.

Imibuzo Evame Ukubuzwa

Yimuphi umehluko omkhulu phakathi komshini we-lathe we-CNC kanye nesikhungo sokuguqula i-CNC?

Imishini ye-CNC lathe ingamathuluzi omshini akhethekile aklanyelwe ngokuyinhloko ukusika, ukugcoba, ukugoba, kanye nezinto zokumba. Isikhungo sokuphendula se-CNC, ngakolunye uhlangothi, sihlanganisa amakhono engeziwe afana nokugaya kanye nokuthepha, okuyenza ibe inketho eguquguqukayo yezinqubo eziyinkimbinkimbi zemishini.

Ngabe izikhungo zokujika eziqondile ziqhathaniswa kanjani namalebula endabuko ngokwamakhono okwenza imishini?

Izikhungo zokujika eziqondile ziwuhlobo lomshini we-CNC lathe osebenza ngomumo wokuphotha oqondile. Lokhu kumisa kunenzuzo ikakhulukazi kuma-workpieces asindayo, amakhulu. Ngokuphambene, amalebula endabuko ngokuvamile afaka i-spindle evundlile futhi afaneleka kangcono amaphrojekthi alula, amancane.

Ihluke ngaziphi izindlela inqubo yokwenza imishini ye-CNC ezikhungweni zokuphendula ihluke kuleyo yemishini ye-CNC lathe?

Inqubo yomshini we-CNC ezikhungweni zokujika ihlukile emishinini ye-CNC lathe ngoba izikhungo zokujika zingenza kokubili ukujika nokugaya ngaphandle kokushintsha ukusetha, okuthuthukisa ukusebenza kahle kokukhiqiza. Imishini ye-CNC lathe, ngenkathi isebenza kahle kakhulu, ngokuvamile igxila ekuguquleni imisebenzi kuphela.

Kungani umkhiqizi engakhetha i-CNC lathe phezu kwesikhungo sokuphendula se-CNC sezinhlelo zokusebenza ezithile?

Abakhiqizi bangase bakhethe i-CNC lathe phezu kwesikhungo sokuphendula se-CNC sezinhlelo zokusebenza ezidinga ukuguqulwa okuzinikele ngaphandle kwesidingo sezinqubo ezengeziwe zokugaya noma zokumba. Amalebula e-CNC ngokuvamile alula futhi angabizi kakhulu kunezikhungo zokujika ezivundlile, okuwenza afanelekele imisebenzi yemishini eqondile.

Isiphetho

Sengiphetha, isinqumo phakathi kwelathe ye-CNC kanye nesikhungo sokuvula i-CNC ekugcineni sincike ezidingweni ezithile zokukhiqiza zomkhiqizi. Imishini ehlanganisiwe inganikeza ukuguquguquka okwengeziwe nokusebenza kahle, kodwa ingase ingafaneleki kuzo zonke izinhlobo zemikhiqizo. Kubalulekile ukuhlola ngokucophelela izidingo zakho zokukhiqiza ngaphambi kokutshala imali kunoma yimuphi umshini.

Ukwengeza, kubalulekile ukugwema amaphutha avamile njengokukhetha ngokusekelwe kuphela enanini kanye nokudebeselela ukucabangela izinhlelo zokukhula zesikhathi esizayo.I-Breton Precisioninikeza ikhwalithi ephezuluIzinsizakalo zokuguqula i-CNCnokunyeizixazululo zokukhiqiza ngamanani ancintisanayo kanye nezikhathi zokuhola ngokushesha. Xhumana nathi namuhla ngazo zonke izidingo zakho zokukhiqiza!