Ukusetshenziswa Kweshidi Lokwenziwa Kwensimbi Embonini Yezimoto

Ukwenziwa kwensimbi yeshidi kuyinqubo yokukhiqiza ebandakanya ukubumba, ukusika nokuhlanganisa amashidi ensimbi amancane ukuze kwakhiwe imikhiqizo ehlukahlukene. Le nqubo isetshenziswe amakhulu eminyaka ezimbonini ezahlukene, kodwa iye yazuza ukuthandwa okuphawulekayo embonini yezimoto eminyakeni edlule. Ukusetshenziswa kokwakhiwa kwensimbi embonini yezimoto kuye kwashintsha ukukhiqizwa kwezimoto, okwenza kusheshe, kusebenze kahle futhi kungabizi kakhulu.

Kulesi sihloko, sizohlola izinhlelo zokusebenza ezihlukahlukene zeukwenziwa kwensimbi yeshidi embonini yezimoto. Kusukela kumaphaneli omzimba namafreyimu kuya ezingxenyeni zenjini nezici zangaphakathi, ukwakhiwa kweshidi lensimbi kudlala indima ebalulekile ekudaleni izimoto zekhwalithi ephezulu. Sizophinde sixoxe ngezinzuzo zokusebenzisa le ndlela ekukhiqizeni izimoto kanye nomthelela wayo ekwakhiweni okuphelele nokusebenza kwezimoto.

Kuyini ukwenza amashidi ensimbi?

Ukwenziwa kwensimbi yeshidi , eyaziwa nangokuthi i-metalworking noma i-sheet metalworking, inqubo yokuguqula amashidi ayisicaba ezinsimbi ezihlukahlukene abe yizimo nosayizi abahlukene. Kubandakanya ukusika, ukugoba, ukubumba nokuhlanganisa amashidi ensimbi amancane ukuze kwakhiwe imiklamo eyinkimbinkimbi futhi eyinkimbinkimbi. Le nqubo isetshenziswa kabanzi ezimbonini ezahlukahlukene ezifana ne-aerospace, ezokwakha, eze-electronics, futhi-ke, embonini yezimoto.

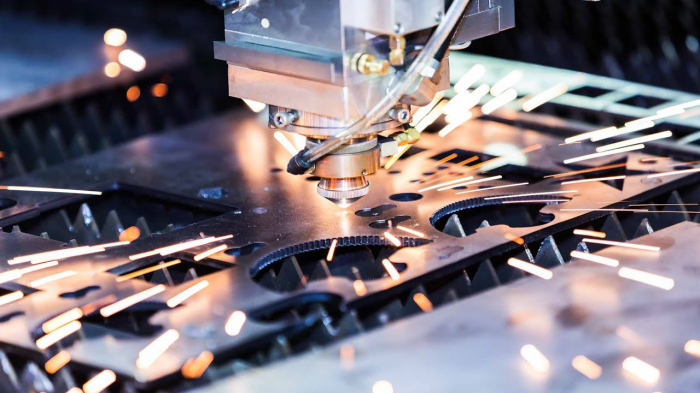

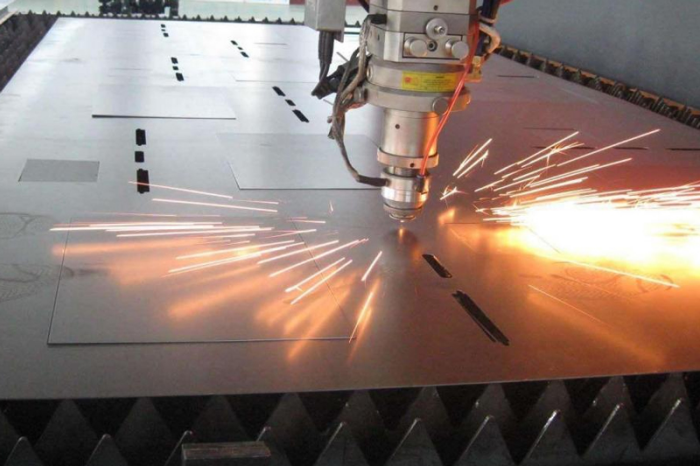

Inqubo yokwenza amashidi ensimbi iqala ngokukhetha impahla eluhlaza. Izinto ezisetshenziswa kakhulu yi-aluminium, insimbi, ithusi, ithusi, nensimbi engagqwali ngenxa yokuqina nokuqina kwazo. Insimbi ekhethiwe ibe isisikwa ibe yisimo oyifunayo kusetshenziswa amathuluzi akhethekile njengabasiki be-laser noma abasiki bendiza yamanzi.

Okulandelayo kuza iisiteji sokugoqa noma sokugoba lapho insimbi yakheka khona ngokomklamo odingekayo. Lokhu ngokuvamile kwenziwa ngosizo lwamabhuleki okucindezela noma ama-roller. Uma insimbi isigobile, iyashisela ukuze ihlanganise izingcezu ezihlukene futhi yakhe isakhiwo esiqinile.

Isigaba sokugcina ekwakhiweni kweshidi lensimbi siyaphela. Lokhu kuhilela ukusendwa kwesihlabathi, ukugaya, nokupholisha indawo engaphezulu ukuze kufinyelele isiphetho esibushelelezi nesingenasici. Amasu engeziwe afana nokudweba, ukumboza ngempushana, kanye ne-anodizing nakho kungasetshenziswa ukuthuthukisa ukubukeka nokuvikela insimbi ekugqwaleni.

Izicelo eziphezulu zokwenziwa kweshidi lensimbi embonini yezimoto

Kunezicelo ezingenakubalwa zeukwenziwa kwensimbi yeshidi embonini yezimoto, kodwa ezinye ezivame kakhulu zihlanganisa amaphaneli omzimba, amafreyimu, izingxenye zenjini, nezici zangaphakathi. Ake sibhekisise lolu hlelo lokusebenza ngalunye:

Amapaneli omzimba

Amaphaneli omzimba awungqimba olungaphandle kakhulu lomzimba wemoto oluvikela ingaphakathi futhi lunikeze ukusekela kwesakhiwo. Lokhu kuhlanganisa iminyango, ihood, isiqu, izinsimbi nophahla. Ukwenziwa kwensimbi yeshidi kusetshenziselwa ukudala lawa maphaneli ngenxa yekhono lawo lokukhiqiza izingxenye ezincane nezingasindi kodwa eziqinile.

Inqubo iqala ngokuklama umumo wephaneli ngayinye usebenzisa isofthiwe ekhethekile. Uma umklamo usuphothuliwe, amashidi ensimbi asikwa abe yizimo ezinembile kusetshenziswa i-laser noma izisiki zejethi zamanzi. Imiphetho egobile yephaneli ngayinye ibe isishiselwa ndawonye ukuze yakhe isakhiwo esiqinile. Okokugcina, amaphaneli enza izinqubo zokuphothula ezifana nokusahlabathi nokupenda ukuze abukeke kahle futhi angenamthungo.

Amafreyimu

Uhlaka lwemoto lusebenza njengomgogodla wayo, lunikeza ukuzinza nokusekelwa kuyo yonke imoto. Kulapho ukwakhiwa kwensimbi kukhanya khona ngempela, njengoba kuvumela ukwakhiwa kwamafreyimu aqinile futhi aqinile angakwazi ukumelana nesisindo semoto nabakuyo.

Inqubo yokwenza ifreyimu yemoto isebenzisa ukwakhiwa kwensimbi yeshidi ihlanganisa ukusika nokubumba izingcezu zensimbi ezihlukahlukene, njengemishayo namashubhu, ngokusho kwemiklamo ethile. Lezi zingcezu zibe sezishiselwa ndawonye ukuze zakhe uhlaka oluqinile olukwazi ukusekela isisindo nokuhamba kwemoto.

Izingxenye zenjini

Ukwenziwa kwensimbi yeshidi kudlala indima ebalulekile ekudaleni izingxenye zenjini njengama-multifolds, amakhava amavalvu, amapani kawoyela, namasistimu okungenisa umoya. Lezi zingxenye zidinga ukukalwa okunembile kanye nokwakheka okuyinkimbinkimbi ukuze zisebenze kahle, okwenza ukwakhiwa kwensimbi ibe yindlela efanelekile yokukhiqiza kwazo.

Inqubo ihilela ukusika nokubumba amashidi ensimbi ukuze udale ingxenye oyifunayo, kulandelwa izinqubo zokushisela nokuqeda. Ukusetshenziswa kokwenziwa kweshidi lensimbi ezingxenyeni zenjini akuqinisekisi nje kuphela ukuqina kwazo kodwa futhi kusiza ukuthuthukisa ukusebenza nokusebenza kahle kwenjini yemoto.

Izici zangaphakathi

Ukwenziwa kwensimbi yeshidi akukhawulelwe ezingxenyeni zangaphandle zemoto; iphinde isetshenziswe ekudaleni izici ezihlukahlukene zangaphakathi njengamadeshibhodi, amaphaneli eminyango, namafreyimu ezihlalo. Lezi zingxenye zidinga ukunemba okuphezulu nokunakwa kwemininingwane ukuze kuqinisekiswe ukufaneleka nokusebenza okufanele, okwenza ukwakhiwa kweshidi lensimbi kube ukukhetha okuhle.

Ngokufanayo nezinye izinhlelo zokusebenza, inqubo iqala ngokuklama umumo wesici ngasinye kusetshenziswa isofthiwe ekhethekile. Amashidi ensimbi abe esesikwa abe yizimo ezinembile kusetshenziswa ama-laser noma amajethi okusika amanzi futhi agobe ngendlela oyifunayo. Izinqubo zokushisela nokuqeda nazo zisetshenziselwa ukwakha ingaphakathi elingenamthungo futhi elibukekayo lemoto.

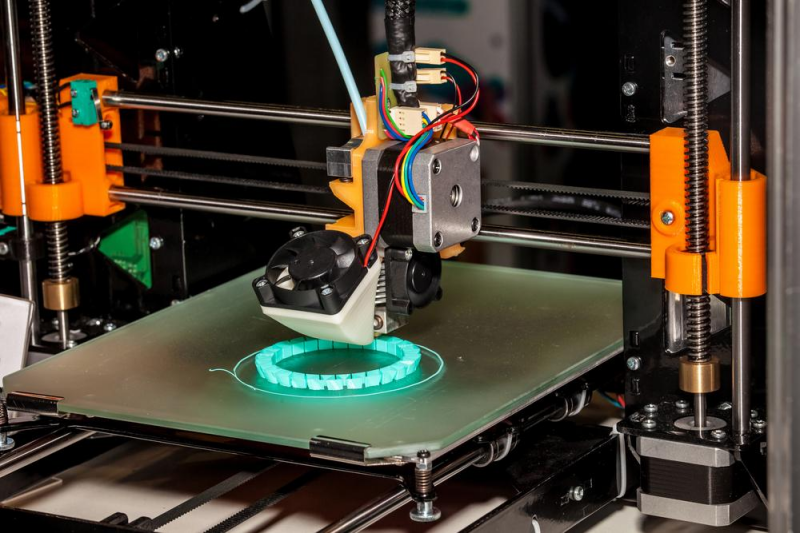

Futhi, ngokuthuthuka kwezobuchwepheshe,ukwenziwa kwensimbi yeshidi manje isetshenziselwa ukwakha izinto zangaphakathi eziphrintiwe ze-3D zezimoto. Lokhu akugcini nje ukunciphisa isikhathi sokukhiqiza nezindleko kodwa futhi kuvumela imiklamo eyinkimbinkimbi futhi eyingqayizivele.

Izinzuzo zokusebenzisa i-sheet metal fabrication embonini yezimoto

Kunezinzuzo eziningi zekusetshenziswa ukwakhiwa kweshidi lensimbi embonini yezimoto. Ezinye zazo zihlanganisa:

- Izikhathi zokukhiqiza ezisheshayo : Ukwenziwa kwensimbi yeshidi kuvumela ukudala ngokushesha izimo eziyinkimbinkimbi nemiklamo, ukunciphisa isikhathi sokukhiqiza nokwandisa ukusebenza kahle enqubweni yokukhiqiza. Futhi, ngokuthuthuka kwezobuchwepheshe, ukuphrinta kwe-3D kwenze ukukhiqizwa kwashesha kakhulu. Ukwengeza, ukusetshenziswa kwesofthiwe ekhethekile esigabeni sokuklama konga isikhathi futhi kunciphisa amaphutha.

- Kuqiza kahle : Ukwenziwa kwensimbi yeshidi kuyindlela engabizi kakhulu yokukhiqiza izingxenye zezimoto njengoba kudinga amathuluzi nezinto zokusebenza ezincane. Iphinde ivumele ukwenza ngokwezifiso okulula nokuguqulwa, ukunciphisa udoti kanye nezindleko zizonke. Futhi ngekhono lokusebenzisa kabusha nokusebenzisa kabusha amashidi ensimbi, kuyasiza futhi ekwehliseni izindleko zezinto ezibonakalayo.

- Imikhiqizo esezingeni eliphezulu futhi ehlala isikhathi eside : Ukwenziwa kwensimbi yeshidi kukhiqiza izingxenye zekhwalithi ephezulu neziqinile ezingamelana nezindawo ezinokhahlo kanye nokuguga okungapheli. Lokhu kuqinisekisa ukuphila isikhathi eside kwezingxenye zezimoto, konga kokubili isikhathi nemali ekushintshweni.

- Ukuguquguquka : Ukwenziwa kwensimbi yeshidi kuyindlela eguquguqukayo engasetshenziswa ukwakha inhlobonhlobo yemikhiqizo enomumo, osayizi, kanye nokucaciswa okuhlukahlukene. Lokhu kuyenza ifaneleke ukukhiqiza izingxenye zezimoto ezahlukahlukene ezidinga amazinga ahlukene okunemba. Ngaphezu kwalokho, ivumela ukuhlanganiswa okulula nezinye izinqubo zokukhiqiza.

- Imikhiqizo engasindi kodwa enamandla : Ukwenziwa kwensimbi yeshidi kukhiqiza izingxenye zezimoto ezingasindi kodwa eziqinile, okuzenza zilungele ukuthuthukisa ukusebenza kahle kukaphethiloli kanye nokusebenza kwemoto iyonke. Lokhu kunenzuzo ikakhulukazi enkambweni ekhulayo yezimoto zikagesi, lapho izingxenye ezingasindi zibalulekile.

- Ukusimama : Ngokukhula kokukhathazeka ngendawo ezungezile, ukwenziwa kweshidi lensimbi kunikeza isisombululo esimeme njengoba kuvumela ukugaywa kabusha nokusetshenziswa kabusha kwezinto. Lokhu akunciphisi udoti kuphela kodwa futhi kwehlisa i-carbon footprint embonini yezimoto.

Ukwenziwa kwensimbi yamashidi kudlala indima ebalulekile embonini yezimoto ngokuhlinzeka ngezixazululo eziphumelelayo, ezibizayo, nezisezingeni eliphezulu zokudala izingxenye ezihlukahlukene. Ukuguquguquka kwayo kanye nokusimama kwayo kuyenza ibe yisu elibalulekile ezinqubweni zesimanje zokukhiqiza izimoto.

Ingabe ukwakhiwa kwensimbi yeshidi kunemikhawulo embonini yezimoto?

Ngenkathi ishidi lensimbiukukhiqiza kunikeza izinzuzo eziningi embonini yezimoto, nayo inemikhawulo ethile okufanele icatshangelwe. Lokhu kubandakanya:

- Imikhawulo yedizayini : Ukwenziwa kwensimbi yeshidi kulinganiselwe ekudaleni izingxenye ezinomumo nemiklamo elula uma kuqhathaniswa. Ingase ingafaneleki ukukhiqiza izingxenye ezinemiklamo eyinkimbinkimbi neyinkimbinkimbi.

- Ukutshalwa kwezimali kokuqala : Nakuba ukwakhiwa kweshidi lensimbi kungasindisa imali ngokuhamba kwesikhathi, kudinga ukutshalwa kwezimali okubalulekile kokuqala kwemishini kanye nesofthiwe ekhethekile. Lokhu kungase kungenzeki kubakhiqizi bezimoto ezincane noma labo abanesabelomali esilinganiselwe.

- Izidingo zabasebenzi abanamakhono : Inqubo yokwenza amashidi ensimbi idinga izisebenzi ezinekhono eziqeqeshelwe ukusebenzisa imishini ekhethekile nesofthiwe. Lokhu kwengeza ezindlekweni zokukhiqiza futhi kungase kungatholakali kalula kuzo zonke izindawo.

- Ukulinganiselwa kwezinto ezibonakalayo : Ukwenziwa kwensimbi yeshidi kukhawulelwe ekusebenziseni izinhlobo ezithile zezinsimbi, njengensimbi, i-aluminium, noma ithusi. Lokhu kungase kukhawulele izinketho zokuklama zezingxenye ezithile zezimoto ezidinga izinto ezihlukile.

- Izinselele zokulawula ikhwalithi : Ngezinqubo ze-welding manual kanye nezinqubo zokuqeda ezihilelekile ekwenziweni kweshidi lensimbi, ukugcina ukuvumelana kanye nekhwalithi kungaba inselele. Lokhu kungase kubangele ukuhluka kwamandla nokuqina kwemikhiqizo yokugcina.

Nokho, le mikhawulo inganqotshwa ngokuhlela okufanele, ukuqeqeshwa, kanye nentuthuko kwezobuchwepheshe. Njengoba ukwakhiwa kwensimbi yeshidi kuqhubeka nokuthuthuka futhi kuthuthuka, kuseyindlela ebalulekile embonini yezimoto ekwakheni izingxenye zekhwalithi ephezulu nezihlala isikhathi eside.

Ingabe ukwenza amashidi ensimbi kunawo umthelela ekwakhiweni kwemoto?

Ukwenziwa kwensimbi yeshidi inomthelela omkhulu ekwakhiweni kwemoto. Ngekhono layo lokudala izimo eziyinkimbinkimbi nezinembayo, ivumela imiklamo eyengeziwe yokudala neyingqayizivele ebingenzeki ngaphambili. Lokhu kubonakala embonini yezimoto yesimanje, lapho sibona khona izimoto ezibukekayo, ezicijile nemininingwane eyinkimbinkimbi.

Ukusetshenziswa kwesoftware ekhethekile esigabeni sokuklama nakho kudlala indima ebalulekile ekwakhiweni kwemoto. Ivumela abaklami ukuthi babone ngeso lengqondo imibono yabo futhi benze izinguquko ngaphambi kokukhiqiza, iqinisekisa ukunemba nokusebenza komkhiqizo wokugcina. Futhi, ngokuthuthuka kwezobuchwepheshe, ukuphrinta kwe-3D kwenze abaklami bakwazi ukuletha imiklamo eqanjiwe ekuphileni ngokushesha.

Ngaphezu kwalokho, imvelo engasindi yezingxenye ezakhiwe ngeshidi lensimbi inomthelela ngokuqondile ekwakhiweni kwemoto. Ngokuthandwa okukhulayo kwezimoto zikagesi, izinto ezingasindi zibalulekile ekuthuthukiseni ukusebenza kahle kukaphethiloli kanye nokusebenza kwemoto kukonke. Lokhu kuholele ekutheni abakhiqizi bezimoto basebenzise ukwenza amashidi ensimbi ukuze bakhe izingxenye ezingasindi kodwa eziqinile, okuvumela imiklamo esebenza kahle kakhulu.

Ngaphezu kwalokho,ukwakhiwa kweshidi lensimbi ukuphumelela kwezindleko kanye nokuguquguquka nakho kube nomthelela ekwakhiweni kwezimoto. Ivumela ukwenza ngokwezifiso okulula nokulungiswa, inikeze abaklami inkululeko eyengeziwe yokuhlola izimo nosayizi abahlukene ngaphandle kokukhathazeka ngezindleko eziphezulu zokukhiqiza. Ngaphezu kwalokho, ukuhambisana kwayo nezinye izinqubo zokukhiqiza kwenza kube lula ukuhlanganisa izingxenye ezakhiwe ngensimbi emiklamweni yemoto iyonke.

Indlela Yokukhulisa Izinzuzo Zokwenziwa Kweshidi Lensimbi Embonini Yezimoto?

Ukwandisa izinzuzo zeukwenziwa kwensimbi yeshidiembonini yezimoto, abakhiqizi bezimoto bangathatha izinyathelo ezilandelayo:

Okokuqala, ukutshala imali kumishini ethuthukisiwe nesoftware kungathuthukisa ukusebenza kahle kanye nekhwalithi yezinqubo zokwenziwa kwensimbi yeshidi. Lokhu kuhlanganisa isofthiwe ye-computer-aid design (CAD), amaphrinta e-3D, nemishini yokushisela irobhothi.

Okwesibili, ukuhlinzeka ngamathuba okuqeqeshwa nokuthuthukiswa kwamakhono kubasebenzi kungaqinisekisa ukuthi banolwazi ngamasu akamuva nobuchwepheshe bokwenza amashidi ensimbi. Lokhu kuzoholela ekukhiqizeni okungcono kanye nokungaguquguquki ekukhiqizeni.

Okwesithathu, ukufaka izinqubo zokusimama ezifana nokusebenzisa izinto ezigaywe kabusha noma ukusebenzisa izindlela zokonga amandla kunganciphisa umthelela wemvelo wokwenziwa kwensimbi embonini yezimoto.

Ngaphezu kwalokho, ukusebenzisana nabahlinzeki abanikezela ngezinto zekhwalithi ephezulu ngamanani ancintisanayo kungasiza ukukhulisa izindleko ngenkathi kugcinwa ikhwalithi yomkhiqizo.

Amathiphu Okukhetha Inkampani Elungile Yokwenza Insimbi Yeshidi

Ukukhetha okulungileinkampani yokwenza amashidi ensimbi kubalulekile ekuqinisekiseni ukukhiqizwa kwezingxenye zezimoto ezisezingeni eliphezulu futhi ezingabizi kakhulu. Amanye amathiphu okufanele uwacabangele lapho ukhetha inkampani yokukhiqiza insimbi ahlanganisa:

- Ubuchwepheshe nolwazi : Bheka inkampani enolwazi olunzulu ekuhlinzekeni ngezinsizakalo zokwenziwa kwensimbi yeshidi, ikakhulukazi embonini yezimoto. Lokhu kuzoqinisekisa ukuthi banobuchwepheshe obudingekayo bokuphatha izinto ezihlukene kanye nemiklamo.

- Izinyathelo zokulawula ikhwalithi: Buza mayelana nezinqubo zokulawula ikhwalithi zenkampani ukuze uqinisekise ukuthi zithobela izindinganiso eziqinile futhi zikhiqiza imiphumela engaguquki.

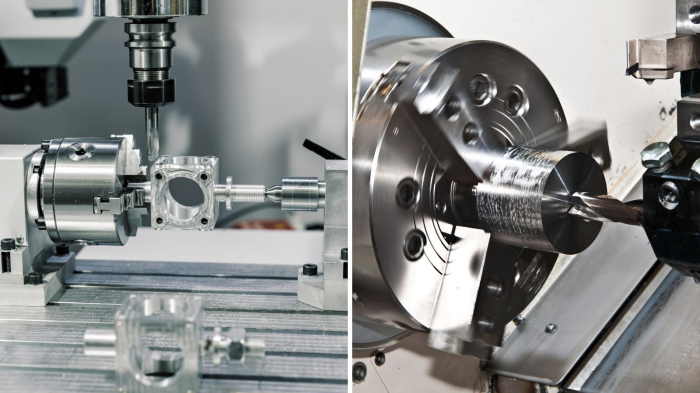

- Ubuchwepheshe kanye nemishini : Cwaninga izinhlobo zobuchwepheshe nemishini esetshenziswa inkampani. Imishini ethuthuke kakhulu ingathuthukisa ukusebenza kahle, ukunemba, nokungaguquguquki ekukhiqizeni.

- Ukuvumelana nezimo nokwenza ngokwezifiso : Khetha inkampani enikeza ukuguquguquka kwezinketho zokuklama nokwenza ngokwezifiso. Lokhu kuzovumela izingxenye zezimoto ezihlukile nezenziwe ngezifiso.

- Ukusebenza kahle kwezindleko: Qhathanisa izingcaphuno ezivela ezinkampanini ezihlukene ukuze uthole inketho engabizi kakhulu ngaphandle kokuyekethisa ikhwalithi.

- Ukuxhumana kanye nesevisi yamakhasimende : Ukuxhumana kubalulekile ohlelweni lokukhiqiza. Bheka inkampani ephendulayo, esobala, futhi ehlinzeka ngesevisi yamakhasimende enhle kakhulu kuyo yonke iphrojekthi.

Kubalulekile ukucwaninga ngokucophelela futhi uqhathanise izinkampani ezihlukene zokwenziwa kwensimbi ngaphambi kokukhetha eyodwa. Ngokucabangela izici ezinjengobuchwepheshe, ubuchwepheshe, ukuphumelela kwezindleko, nokuxhumana, abakhiqizi bezimoto bangaqinisekisa ukuthi babambisana nenkampani ethembekile nenekhono yokwenza amashidi ensimbi.

Xhumana ne-Breton Precision Ngezidingo Zakho Zokwenziwa Kweshidi Lensimbi

NgoI-Shenzhen Breton I-Precision Model Co., Ltd., siyaziqhenya ngokuba ngabahlinzeki bekhwalithi ephezulu abahlinzeka ngezinsizakalo eziphelele zokucubungula indawo eyodwa kuzo zonke izidingo zokukhiqiza. Ngokukhiqiza kwethu okuthambile nezinqubo ezisebenzayo, sizinikele ekunikezeni izixazululo ezingcono kakhulu kumakhasimende ethu.

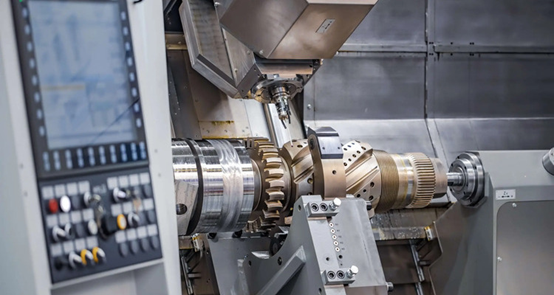

Futhi sicacisa kuUkusika i-Laser yokucubungula insimbi yeshidi,insimbi engagqwali sheet metal processing,izingxenye zethusi sheet metal processing,ukucubungula insimbi yensimbi yethusifuthialuminium ingxubevange sheet metal ukucubungula. Eyethuimishini ethuthukisiwe ihlanganisaizikhungo zemishini ye-CNC engu-3-eksisi, 4-eksisi kanye ne-5-eksisi, okusivumela ukuthi siphathe amajiyometri ayinkimbinkimbi kanye nezidingo eziphezulu zobuhle.

Ngemishini yethu yesimanje kanye nezinsiza, sisebenza ngokukhethekileCNC imishini,ukubumba umjovo wepulasitiki,ukwenziwa kwensimbi yeshidi,ukukhishwa kwe-vacuum, futhiUkuphrinta kwe-3D . Ithimba lethu lochwepheshe lingakwazi ukuphatha amaphrojekthi asukela ekukhiqizeni okuyisibonelo kuya ekukhiqizeni ngobuningi kalula.

Ngakho-ke sishayele ku-0086 0755-23286835 ukuze sixoxe ngeyakhoIzidingo zokwenza amashidi ensimbi . Ithimba lethu lizibophezele ekuhlinzekeni ngezinsizakalo ezisezingeni eliphezulu kanye nokuletha imikhiqizo yekhwalithi ephezulu ehlangabezana nedlula okulindele.

Imibuzo Evame Ukubuzwa

Asetshenziswa kanjani amasu okwenziwa kwensimbi ekukhiqizeni izimoto?

Izindlela zokwenziwa kwensimbi yeshidi zibalulekile ekukhiqizeni izimoto, lapho ukunemba nokuqina kubaluleke kakhulu. Lawa masu ahlanganisa ukusika, ukugoba, nokuhlanganisa insimbi ukuze kwakhiwe izingxenye eziyinkimbinkimbi njengemizimba yezimoto namafreyimu, nezinhlelo zokukhipha umoya, kusetshenziswa amathuluzi afana nemishini ye-lathe ye-CNC kanye nokucindezela.

Iyiphi indima edlalwa abakhiqizi bensimbi ekwakhiweni kwensimbi yezimoto?

Abakhi bensimbi babalulekile embonini yezimoto, njengoba benza imiklamo ibe nempilo ngokuguqula amashidi asicaba ensimbi abe izingxenye zesakhiwo. Ekwenziweni kwensimbi yensimbi yezimoto, ubuchwepheshe babo buqinisekisa ukuthi izingxenye ezifana namaphaneli nezingxenye ze-chassis zihlangabezana nokucaciswa okuqondile kanye namazinga ekhwalithi.

Kungani ukwakhiwa kwensimbi yezimoto kubalulekile ekukhiqizeni imizimba yezimoto namafreyimu?

Ukwakhiwa kwensimbi yezimoto kubalulekile ekukhiqizeni imizimba yezimoto namafreyimu ngoba kunikeza amandla, ukuguquguquka, nokunemba okudingekayo kulezi zingxenye ezibalulekile. Besebenzisa izindlela zokwenziwa ezithuthukisiwe, abakhiqizi bangaqinisekisa ukuthi lezi zingxenye zensimbi zeshidi zingamelana nobunzima bokusetshenziswa futhi zihlangabezane nezindinganiso zokuphepha.

Yiziphi izinzuzo ezinikezwa ukwenziwa kwensimbi yezimoto zokwenza amasistimu wokukhipha umoya?

Ukwakhiwa kweshidi lensimbi yezimoto kunikeza izinzuzo ezibalulekile ekwenzeni amasistimu e-ehaust, njengokuqina okuphakeme nokulingana okuhambisanayo. Abakhi bangakha amasistimu akhipha amagesi ngokuphumelelayo enjinini, athuthukise ukusebenza kahle futhi anciphise ukungcola, okubalulekile ekuhlangabezaneni nemithethonqubo yezemvelo.

Isiphetho

Ekuphetheni,ukwenziwa kwensimbi yeshidi idlala indima ebalulekile embonini yokwenziwa kwezimoto. Ivumela ukukhiqizwa kwezingxenye ezingasindi, ezihlala isikhathi eside, nezijabulisa ngobuhle ezibalulekile eziklanyweni zesimanje zezimoto.

Ngokutshala imali ezintweni ezithuthukisiwe, ukunikeza abasebenzi amathuba okuqeqesha, ukufaka izinqubo ezizinzile, nokusebenzisana nabahlinzeki abathembekile, abakhiqizi bezimoto bangakwazi ukwandisa izinzuzo zokwenziwa kweshidi lensimbi.

Ngaphezu kwalokho, kubalulekile ukukhetha ngokucophelela inkampani ekhiqiza amashidi ngokusekelwe emakhono ayo, ubuchwepheshe, ukusebenza kahle kwezindleko, nokuxhumana. NgoI-Breton Precision Model Co., Ltd., sinikezela ngezinsizakalo zekhwalithi ephezulu ngamanani ancintisanayo futhi sizinikele ekuhlangabezaneni nezidingo zamakhasimende ethu.