Ente Molding Materials

Breton Precision e fana ka litšepe tse tloaelehileng bakeng sa lisebelisoa tsa ho bopa ente, le lisebelisoa tse fapaneng tsa polasetiki tse tsebahalang.

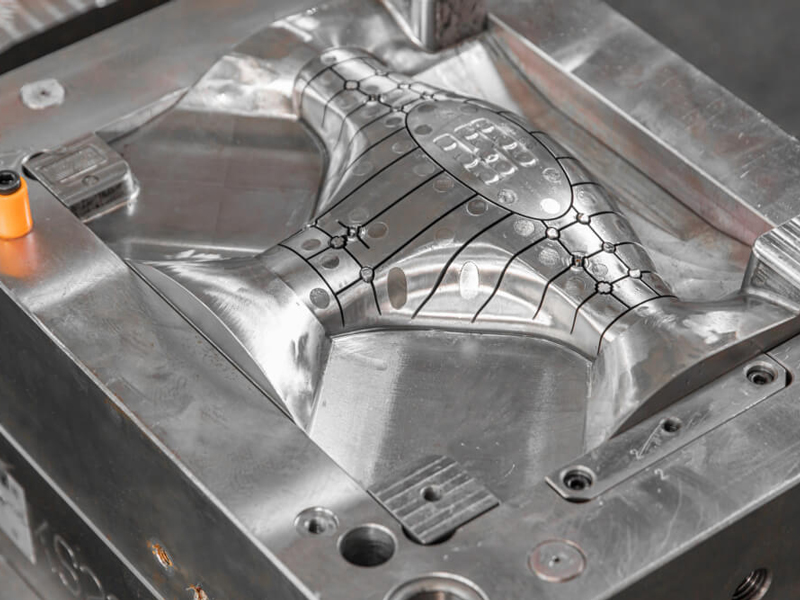

Ente Mold Tooling Materials

Thermoplastic

Thermoset

Rabara ea Silicone ea Mokelikeli | Epoxy |

Polyurethane | Phenolic |

Ente Mold Surface Finishes

Haholo-holo re fana ka li-sPI tsa liforomo tsa ente ea polasetiki. Bakeng sa masela a VDI, hlakisa litlhoko tsa hau ha u romella tlhahiso ea hau sethaleng sa rona.

SPI Qetella Maemo | Surface Roughness RA (mm) | Mokhoa oa ho qetela | Sebopeho | Litšepe Tse khothalelitsoeng |

SPI A1 | 0.012 ho ea ho 0.025 | 6000 Grit Diamond | Qetello ea Super High Glossy | S136 (54HRC) kapa 8407(52HRC) |

SPI A2 | 0.012 ho ea ho 0.025 | 3000 Grit Diamond | Qetello e benyang e phahameng | S136 (54HRC) kapa 8407(52HRC) |

SPI A3 | 0.05 ho 0.10 | 1200 Grit Diamond | Tloaelehileng Glossy qete | S136 (300HB) kapa 718H |

SPI B1 | 0.05 ho 0.10 | 600 Grit Pampiri | Qetello e ntle ea Semi-glossy | 718H |

SPI B2 | 0.10 ho isa ho 0.15 | 400 Grit Pampiri | Qetello e mahareng e benyang | 718H |

SPI B3 | 0.28 ho ea ho 0.32 | 320 Grit Pampiri | Qetello e tloaelehileng ea Semi-glossy | 718H |

SPI C1 | 0.35 ho ea ho 0.40 | 600 Grit Stone | Qetello e ntle ea Matte | 718H |

SPI C2 | 0.45 ho ea ho 0.55 | 400 Grit Stone | Qetellong ea Matte e mahareng | 718H |

SPI C3 | 0.63 ho ea ho 0.70 | 320 Grit Stone | Tlhōlo e tloaelehileng ea Matte | 718H |

SPI D1 | 0.80 ho isa ho 1.00 | Dry Blast Glass Bead | Qetello e entsoeng ka Satin | 718H |

SPI D2 | 1.00 ho 2.80 | Ho phatloha ho omileng | Qetello e Dull Textured | 718H |

SPI D3 | 3.20 ho ea ho 18.0 | Ho phatloha ho omileng | Qetello e Rough Textured | 718H |

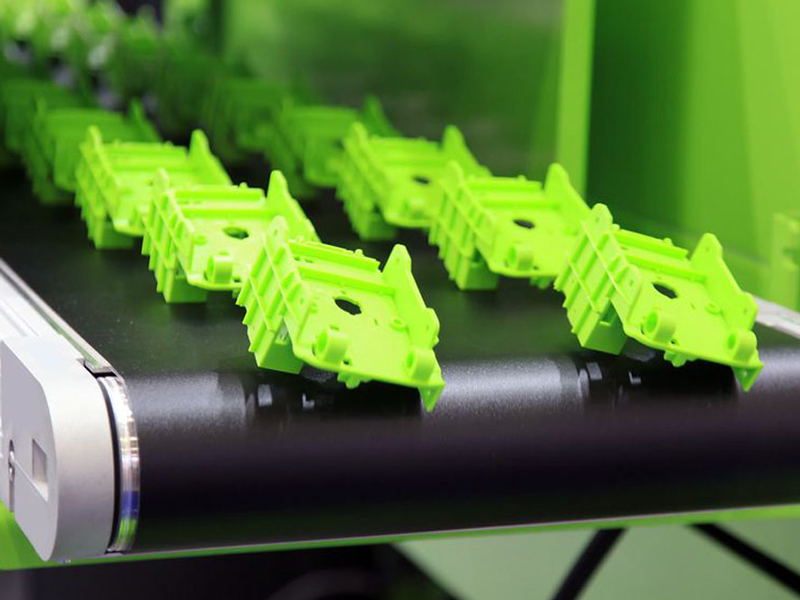

Lihlopha tsa Ente Mold

Re khomarela mekhahlelo e mehlano e tloaelehileng ea likarolo tsa hlobo ea SPI ho tloha ho Sehlopha sa 101 ho ea ho sa 105, ho hokahanya litebello bakeng sa bareki le bafani ba thepa ka ho tšoana.

Sehlopha sa Mold | Boemo ba Tlhahiso | Lipotoloho | Lisebelisoa | Mamello | Litšenyehelo | Lead time |

Sehlopha sa 105 | Tlase haholo | Ka tlase ho li-cycle tse 500 | Teko ea mohlala | ± 0.02mm | Ho theko e tlaase ho hlahisa palo e fokolang haholo ea lihlahisoa tsa lihlahisoa | Matsatsi a 7-10 |

Sehlopha sa 104 | Tlase | Lipotoloho tse ka tlase ho 100K | E ntle bakeng sa likarolo tse fokolang tsa tlhahiso e nang le lisebelisoa tse sa cheng | ± 0.02mm | E oela ka har'a mekhahlelo e tlase ho isa ho e mahareng | Matsatsi a 10-15 |

Sehlopha sa 103 | Mahareng

| Lipotoloho tse ka tlase ho 500K | Bakeng sa likarolo tse tlase ho isa ho tse mahareng | ± 0.02mm | Oele ka har'a mekhahlelo e tloaelehileng ea litheko | Matsatsi a 10-15 |

Sehlopha sa 102 | Mahareng ho isa holimo | Ka tlase ho 1M | E ntle bakeng sa likarolo tse nang le lisebelisoa tsa abrasive le / kapa mamello e thata | ± 0.02mm | Theko e phahameng ka toka ebile e entsoe ka thepa ea boleng bo holimo | Matsatsi a 10-15 |

Sehlopha sa 101 | E phahameng haholo | Lipotoloho tse fetang 1M | Tlhahiso e phahameng haholo le linako tsa potoloho e potlakileng | ± 0.02mm | Theko e phahameng ka ho fetisisa ebile e entsoe ka thepa ea boleng bo holimo feela | Matsatsi a 10-18 |