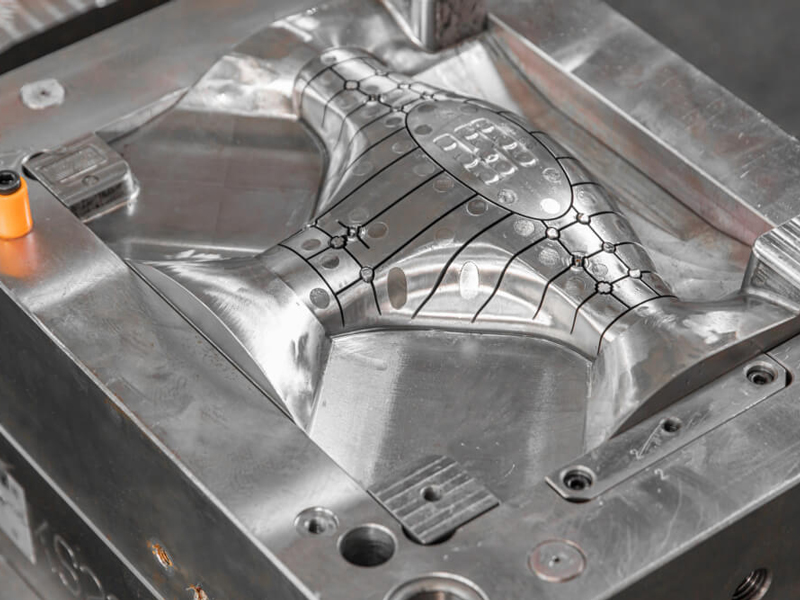

Qalabka wax lagu Durayo

Breton Precision waxay bixisaa biro caadi ah oo loogu talagalay qalabaynta qaabaynta duritaanka, iyo noocyo kala duwan oo qalab caag ah oo caan ah.

Qalabka Qalabaynta Caaryada ee Durida

Thermoplastic

Thermoset

Rubber Silikoon dareere ah | Epoxy |

Polyurethane | Phenolic |

Dusha duritaan ee caaryada ayaa dhammaatay

Waxaanu ugu horayn siinaa SPI-da dhamaystirka caaryada la isku duro. Qoraallada VDI-da, qeex shuruudahaaga marka aad soo gudbinayso xigashadaada madalkeenna.

SPI Dhamaystirka Heerarka | Dusha sare ee Roughness RA (mm) | Habka Dhamaystirka | Texture | Biraha lagu taliyay |

SPI A1 | 0.012 ilaa 0.025 | 6000 Grit Diamond | Dhammaystirka dhalaalaya sare ee sare | S136 (54HRC) ama 8407(52HRC) |

SPI A2 | 0.012 ilaa 0.025 | 3000 Grit Diamond | Dhammays heersare ah oo dhalaalaya | S136 (54HRC) ama 8407(52HRC) |

SPI A3 | 0.05 ilaa 0.10 | 1200 Grit Diamond | Dhammaadka dhaldhalaalka caadiga ah | S136 (300HB) ama 718H |

SPI B1 | 0.05 ilaa 0.10 | 600 Waraaqo Jaranjaro ah | Dhammayn Semi- dhalaalaysa oo Fiican | 718H |

SPI B2 | 0.10 ilaa 0.15 | 400 oo warqad ah | Dhammaadka Semi- dhaldhalaalka dhexdhexaadka ah | 718H |

SPI B3 | 0.28 ilaa 0.32 | 320 warqad xariijimo ah | Dhammaystirka Semi-glossy caadiga ah | 718H |

SPI C1 | 0.35 ilaa 0.40 | 600 Grit Stone | Dhammaystirka Matte Fine | 718H |

SPI C2 | 0.45 ilaa 0.55 | 400 Grit Stone | Dhammaystir dhexdhexaad ah | 718H |

SPI C3 | 0.63 ilaa 0.70 | 320 Grit Stone | Dhammaystirka matte caadiga ah | 718H |

SPI D1 | 0.80 ilaa 1.00 | Qurxinta Qurxinta Qalalan | Dhammaadka Satin Textured | 718H |

SPI D2 | 1.00 ilaa 2.80 | Qarax Qalalan | Dhammaadka qoraalka Dull | 718H |

SPI D3 | 3.20 ilaa 18.0 | Qarax Qalalan | Dhammayn adag Textured | 718H |

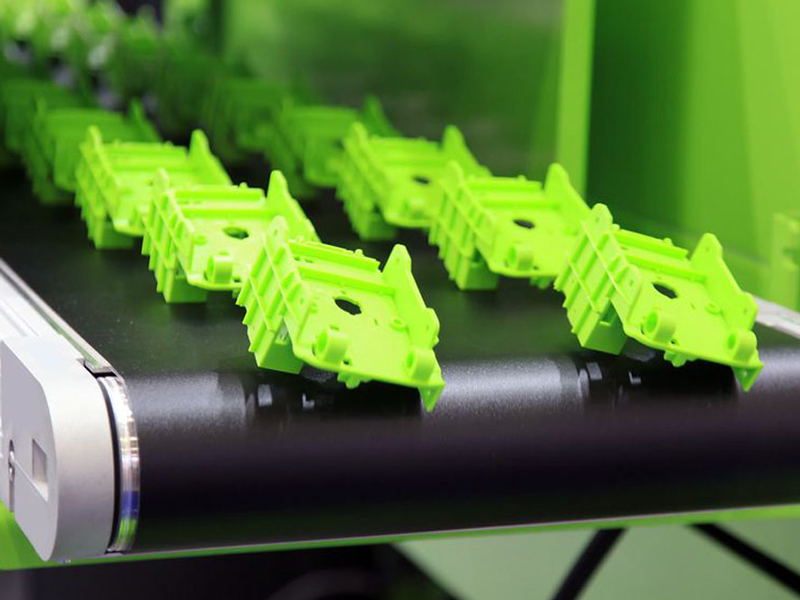

Qaybaha caaryada la isku duro

Waxaan u hoggaansanahay shanta qaybood ee caadiga ah ee kala soocida caaryada SPI ee fasalka 101 ilaa 105, iyadoo la waafajinayo filashada macaamiisha iyo alaab-qeybiyeyaasha si isku mid ah.

Heerka caaryada | Heerka Wax-soo-saarka | Wareegtada | Codsiyada | Dulqaad | Qiimaha | Waqtiga Hogaaminta |

Fasalka 105 | Aad u hooseeya | In ka yar 500 wareeg | Tijaabada prototype | ± 0.02mm | Aan qaali ahayn si loo soo saaro tiro aad u xaddidan oo ah noocyada alaabta | 7-10 maalmood |

Fasalka 104 | Hoose | In ka yar 100K wareegyo | U fiican qaybaha wax soo saarka xaddidan oo leh walxo aan xoqin | ± 0.02mm | Ku dhex dhaca kala duwanaanshaha qiimaha hooseeya ama dhexdhexaadka ah | 10-15 maalmood |

Fasalka 103 | Dhexdhexaad

| In ka yar 500K wareegyo | Qaybaha wax soo saarka hooseeya iyo kuwa dhexdhexaadka ah | ± 0.02mm | Ku dhaca qiimaha caadiga ah | 10-15 maalmood |

Fasalka 102 | Dhexdhexaad ilaa sare | In ka yar 1M | U fiican qaybaha leh walxaha xoqan iyo/ama dulqaadka adag | ± 0.02mm | Sicir sare leh oo lagu sameeyay alaab tayo sare leh | 10-15 maalmood |

Fasalka 101 | Aad u sarreeya | In ka badan 1M wareegyo | Wax soo saar aad u sarreeya iyo waqtiyada wareegyada degdega ah | ± 0.02mm | Qiimaha ugu sarreeya oo lagu sameeyay kaliya qalabka tayada ugu sarreeya | 10-18 maalmood |