CNC Machining Motorcycle Parts: Making High-End Custom Parts

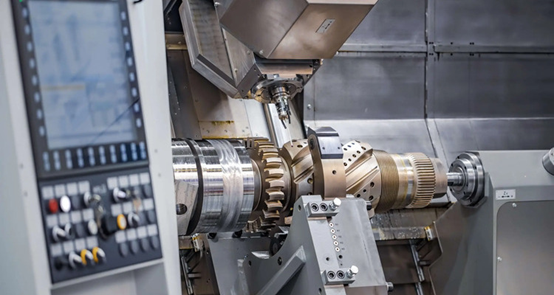

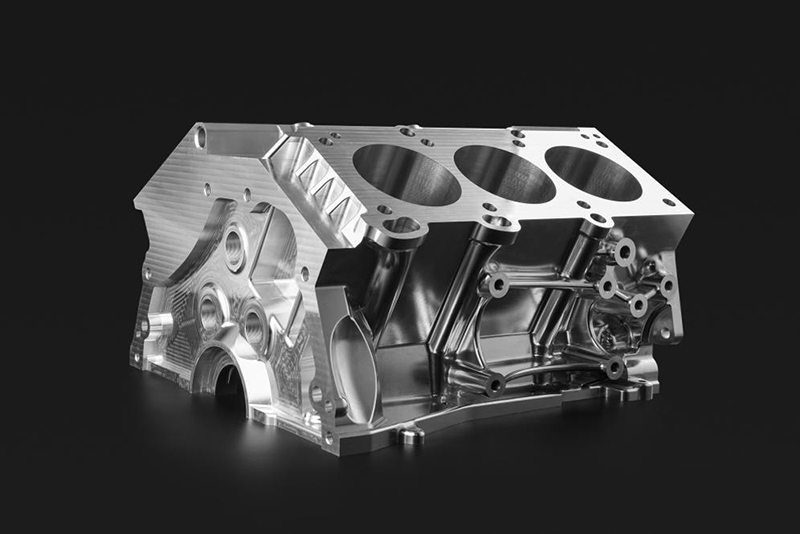

CNC machining has revolutionized the manufacturing industry, allowing for the creation of high-quality custom parts with unparalleled precision and detail. This technology has especially impacted the motorcycle industry, where unique and specialized parts are in high demand among riders looking to customize their bikes.

One area where CNC machining has made a significant impact is in creating customized motorcycle parts. From handlebars to footpegs, brake calipers to exhaust pipes, virtually any component on a motorcycle can be manufactured using this cutting-edge technology.

In this article, we'll dive into how CNC machining is used to create high-end custom motorcycle parts and explore some of the benefits and challenges of using this technology in the motorcycle industry. We'll also discuss some popular examples of CNC machined motorcycle parts and how they add to the overall look and performance of a bike.

The Benefits of CNC Machining for Motorcycle Parts

One of the biggest benefits of using CNC machining for motorcycle parts is the level of precision and detail that can be achieved. This technology uses computer-controlled machines to precisely cut and shape the desired part, resulting in a high-quality finished product.

Another advantage is the ability to create complex and intricate designs with ease. Traditional methods of manufacturing such as casting or forging often have limitations when it comes to producing intricate shapes, but CNC machining allows for more freedom in design.

CNC machining also offers a high level of consistency, ensuring that each part produced is nearly identical to the last. This is important for motorcycle manufacturers who need multiple pieces of a specific part for their production line.

In addition, CNC machining allows for faster production times compared to traditional methods. With computer automation, there is less room for human error and parts can be manufactured at a quicker pace.

Challenges Faced in CNC Machining Motorcycle Parts

While CNC machining has many benefits, it also presents some challenges when it comes to manufacturing motorcycle parts. One of the main challenges is cost - this technology requires expensive equipment and specialized software, making it out of reach for smaller businesses or individuals.

Another issue is the learning curve involved in operating CNC machines. It takes time and training to become proficient in using the software and understanding the machine's capabilities. This can also add to the cost of producing customized parts.

In addition, CNC machining is limited by the size of the machines themselves. Parts that are too large or have complex geometries may not be able to be produced with this technology, requiring alternative manufacturing methods.

Popular Examples of Custom Motorcycle Parts Made with CNC Machining

Despite its challenges, CNC machining has been used to create a wide range of custom motorcycle parts, adding to the overall aesthetics and performance of bikes. Some popular examples include handlebars, engine covers, and wheels.

Custom CNC machined handlebars can be made from a variety of materials such as aluminum, steel, or titanium. They can also feature intricate designs and patterns that add a unique touch to the bike's look.

Engine covers are another popular custom part made with CNC machining. These covers not only enhance the appearance of the engine but also provide protection and durability.

CNC machined wheels have also become popular among motorcycle enthusiasts for their lightweight and high-strength properties. These wheels are often designed with unique patterns and finishes to make them stand out on the road.

Plus, with the ability to create custom parts on a smaller scale, individuals can now have one-of-a-kind pieces made specifically for their bikes. This has opened up opportunities for customization and personalization in the motorcycle industry.

Why CNC Machining is the Future of Custom Motorcycle Parts

With its precision, speed, and versatility, CNC machining has become a game-changer for creating custom motorcycle parts. As technology continues to advance and become more accessible, we can expect to see even more innovative and complex designs being produced with this method.

In addition, as the demand for customization grows within the motorcycle industry, CNC machining offers a cost-effective solution for both manufacturers and individuals looking to create unique parts.

From enhancing performance to adding aesthetic appeal, there's no denying that CNC machined motorcycle parts are here to stay. So whether you're a rider looking to upgrade your bike or a manufacturer wanting to offer more options to customers, CNC machining is the way of the future for high-end custom motorcycle parts.

Does Customization Come at a Cost?

Customized motorcycle parts may come with a higher price tag compared to their mass-produced counterparts. This is due to the additional time and resources required for creating unique designs, as well as the cost of using CNC machining technology.

However, many riders are willing to pay the extra cost for the ability to personalize their bikes and stand out from the crowd. In addition, customized parts often offer better performance and durability, making them a worthwhile investment in the long run.

Ultimately, whether customization comes at a cost depends on personal preferences and priorities. For some, it may be worth the extra expense for a one-of-a-kind bike, while others may prefer to stick with more affordable, standard parts. Either way, CNC machining has made customization more accessible and feasible for motorcycle enthusiasts.

Can CNC Machining Ever Fully Replace Traditional Methods?

While CNC machining has certainly revolutionized the way custom motorcycle parts are made, it is unlikely that it will completely replace traditional methods of manufacturing. Some parts may still be better suited to casting or forging processes, depending on their size and complexity.

Moreover, traditional methods have been used for centuries and have proven to be effective in producing durable and high-quality parts. They also offer a sense of artistry and craftsmanship that cannot be replicated with computer automation.

However, as technology continues to advance and become more affordable, we may see an increase in the use of CNC machining for custom motorcycle parts. It offers a level of precision and efficiency that traditional methods cannot match, making it a valuable tool in the industry's future.

So while traditional methods may still have their place, it is clear that CNC machining is here to stay when it comes to creating customized motorcycle parts. With its ability to produce unique designs quickly and accurately, this technology will continue to play a significant role in the customization and innovation of motorcycles for years to come.

How CNC Machining is Impacting the Motorcycle Industry

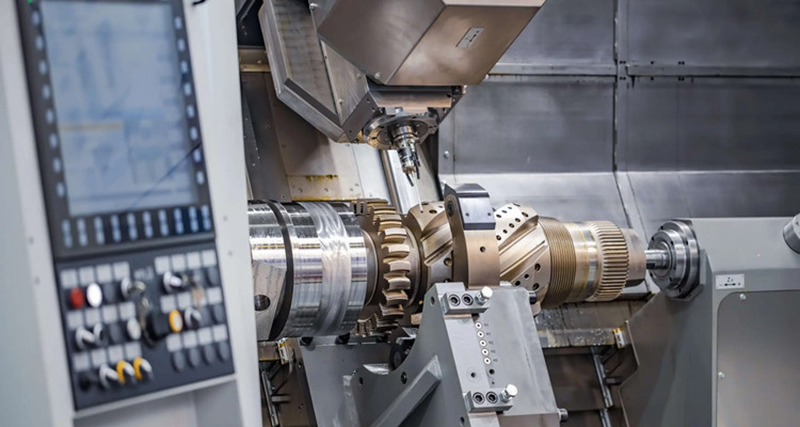

CNC machining has not only revolutionized the way custom motorcycle parts are made but also had a significant impact on the entire industry. This technology has allowed for quicker and more precise production of parts, leading to shorter lead times and increased efficiency.

Moreover, it has opened up opportunities for smaller businesses and individuals to enter the market by offering cost-effective solutions for customization. This has led to a wider range of options for riders when it comes to personalizing their bikes.

In addition, with the ability to produce highly complex designs, CNC machining has pushed the boundaries of what is possible in terms of performance and aesthetics. This has led to the development of new and innovative designs that have helped shape the modern motorcycle industry.

Future Possibilities with CNC Machining

As technology continues to advance, we can expect to see even more possibilities with CNC machining in the motorcycle industry. With the integration of artificial intelligence and machine learning, machines will become smarter and more efficient, allowing for even more complex designs to be created.

In addition, advancements in materials science will also play a significant role in shaping the future of CNC machined motorcycle parts. Stronger and lighter materials may become more readily available, allowing for even higher levels of performance.

Furthermore, as electric motorcycles continue to gain popularity, CNC machining will play an essential role in creating specialized parts for these vehicles. With its ability to produce intricate designs and fine-tune performance, CNC machining will be crucial in pushing the boundaries of what is possible with electric motorcycles.

Tips for Choosing the Right CNC Machining Service for Your Custom Motorcycle Parts

When it comes to choosing a CNC machining service for your custom motorcycle parts, there are a few things to consider. Here are some tips to help you make the right choice:

- Look for experience and expertise in the motorcycle industry- A service with a strong understanding of motorcycles and their components will be better equipped to create high-quality parts. Additionally, they may also be able to provide valuable insights and suggestions for your designs.

- Check their machinery and capabilities- Make sure the service has the necessary equipment and technology to produce your desired parts accurately and efficiently. Plus, having a variety of machines and capabilities can offer more options for customization.

- Inquire about materials and finishes- Ask about the types of materials and finishes they can work with to ensure your parts meet your expectations in terms of strength and aesthetics.

- Consider their turnaround time and pricing- Get an idea of how long it will take for your parts to be produced and their associated costs. This will help you plan accordingly and avoid any surprises.

By keeping these factors in mind, you can choose a CNC machining service that best meets your needs for customized motorcycle parts.

Contact Breton Precision For Your CNC Machining Needs

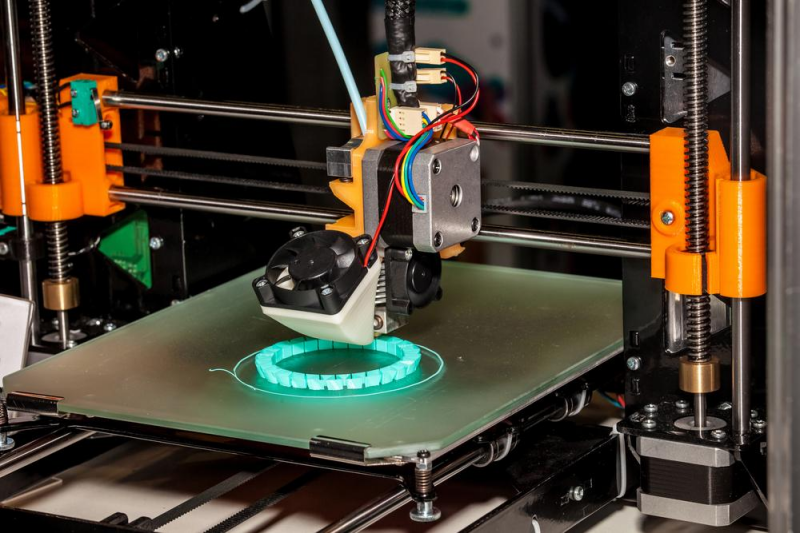

Shenzhen Breton Precision Model Co., Ltd is a trusted and experienced CNC machining service provider with exceptional capabilities in producing custom cnc motorcycle parts. Our company offers a wide range of services including CNC machining, plastic injection molding, sheet metal fabrication, vacuum casting, and 3D printing. Our team of experts can handle projects ranging from prototype production to mass production with ease. We also offer competitive pricing and fast lead times, ensuring that your projects are completed in a timely and cost-effective manner.

Alse we have in-house quality control measures to ensure that all our products meet strict tolerance criteria and quality standards. Our use of advanced CNC machining centers, including 3-axis, 4-axis, and 5-axis machines, allows us to produce parts with complex geometries and high aesthetic demands. Plus, we leverage our expertise in lean production and efficient processes to offer the best solutions for your manufacturing needs.

So Contact Shenzhen Breton Precision Model Co., Ltd today for all your CNC machining needs. Our experienced team is dedicated to providing top-quality products and exceptional customer service. We are conveniently located in Shenzhen, China, and can be reached via phone at 0086 0755-23286835 or email at info@breton-precision.com. Let us help you bring your custom motorcycle parts to life!

FAQs

How do CNC machining services enhance the manufacturing process of custom motorcycle parts?

CNC machining services enhance the manufacturing process of custom motorcycle parts by utilizing computer numerical control (CNC) to achieve high precision and consistency. This technology allows for the efficient production of complex parts like engine components and motorcycle wheels, ensuring that each part meets exact specifications with high-quality finishes.

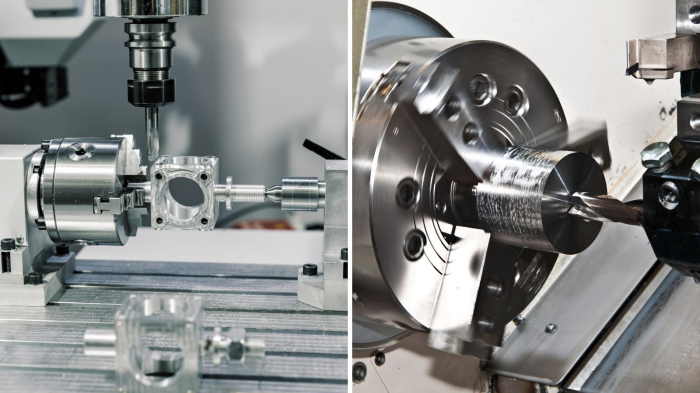

What role does CNC milling play in fabricating custom motorcycle parts?

CNC milling is crucial in fabricating custom motorcycle parts as it enables the precise cutting and shaping of metal components. This process is particularly effective for creating intricate designs and patterns on parts such as motorcycle wheels and other visible motorcycle components, adding both functionality and aesthetic appeal.

Can CNC turning be used for all types of motorcycle parts?

CNC turning is versatile and can be used for manufacturing various round or cylindrical motorcycle components, such as engine parts and axles. This method involves rotating the part against a cutting tool, making it ideal for producing parts that require precise diameters and tight tolerances.

What are the benefits of using CNC machines for manufacturing custom motorcycle parts?

Using CNC machines for manufacturing custom motorcycle parts offers several benefits, including enhanced precision, repeatability, and speed of production. CNC technology allows for complex parts to be made with exact tolerances and minimal waste, making it a preferred choice for producing high-end custom parts in the motorcycle industry.

Conclusion

CNC machining has transformed the motorcycle industry, providing countless opportunities for customization and pushing the boundaries of performance and design. As technology continues to advance, we can expect further developments in CNC machining that will shape the future of motorcycles.

When choosing a CNC machining service for your custom motorcycle parts, consider factors such as experience, capabilities, materials, turnaround time, and pricing. At Shenzhen Breton Precision Model Co., Ltd, we offer top-quality services at competitive prices with fast lead times. Contact us today to see how we can bring your designs to life!

Related searches: Cnc Machining Parts Factory Benefits Of Cnc Machining Precision Cnc Machining China