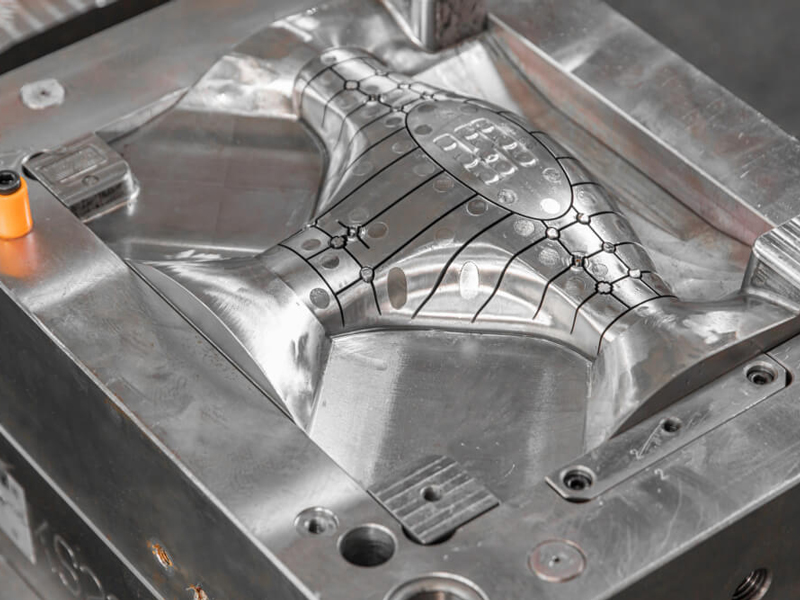

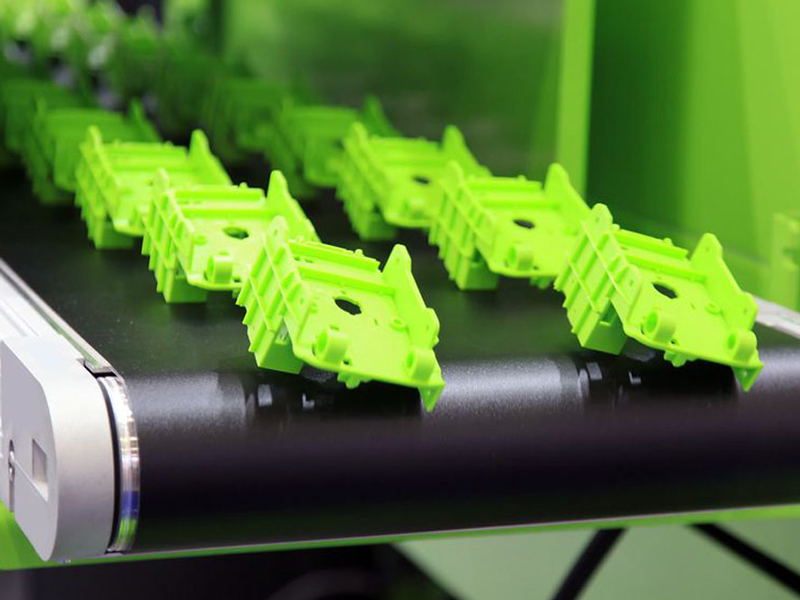

Txhaj Moulding Khoom

Breton Precision muaj cov hlau ntau rau kev txhaj tshuaj molding cuab yeej, thiab ntau yam khoom siv yas nrov.

Txhaj Mould Tooling Materials

Thermoplastic

Thermoset

Liquid Silicone Roj Hmab | Epoxy |

Polyurethane | Phenolic |

Txhaj Mould Surface Finishes

Peb feem ntau muaj SPI tiav rau cov yas txhaj tshuaj pwm. Rau VDI textures, qhia koj cov kev xav tau thaum xa koj cov lus tsocai rau ntawm peb lub platform.

SPI Finish Standards | Nto Roughness RA (mm) | Txoj kev ua tiav | Kev ntxhib los mos | Steels pom zoo |

SPI A1 | 0.012-0.025 Nws | 6000 Pob Zeb Diamond | Super High Glossy tiav | S136 (54HRC) lossis 8407 (52HRC) |

SPI A2 | 0.012-0.025 Nws | 3000 Pob Zeb Diamond | High Glossy tiav | S136 (54HRC) lossis 8407 (52HRC) |

SPI A3 | 0.05-0.10 Nws | 1200 Pob Zeb Diamond | Ib txwm Glossy tiav | S136 (300HB) lossis 718H |

SPI B1 | 0.05-0.10 Nws | 600 Grit Ntawv | Fine Semi-glossy tiav | 718h ib |

SPI B2 | 0.10-0.15 Nws | 400 Grit Ntawv | Nruab nrab Semi-glossy tiav | 718h ib |

SPI B3 | 0.28-0.32 Nws | 320 Grit Ntawv | Ib txwm Semi-glossy tiav | 718h ib |

SPI C1 | 0.35-0.40 Nws | 600 Grit Pob Zeb | Fine Matte tiav | 718h ib |

SPI C2 | 0.45-0.55 Nws | 400 Grit Pob Zeb | Medium Matte tiav | 718h ib |

SPI C3 | 0.63-0.70 Nws | 320 Grit Pob Zeb | Li qub Matte tiav | 718h ib |

SPI D1 | 0.80-1.00 Nws | Dry Blast Glass Bead | Satin Textured tiav | 718h ib |

SPI D2 | 1.00-2.80 Nws | Qhuav Blast | Dull Textured tiav | 718h ib |

SPI D3 | 3.20-18.0 Nws | Qhuav Blast | Rough Textured tiav | 718h ib |

Cov chav kawm ntawm Txhaj Mould

Peb ua raws li tsib yam txheej txheem ntawm SPI pwm kev faib tawm los ntawm Chav Kawm 101 txog 105, ua raws cov kev cia siab rau cov neeg siv khoom thiab cov neeg muag khoom ib yam.

Mould Class | Qib ntau lawm | Lub voj voog | Daim ntawv thov | Ua siab ntev | Nqi | Lub Sijhawm Lead |

Chav Kawm 105 | Tsawg heev | Tsawg dua 500 lub voj voog | Kev sim qauv | ± 0.02 hli | pheej yig los tsim ib tug tsawg tsawg ntawm cov khoom prototypes | 7-10 hnub |

Chav Kawm 104 | Tsawg | Tsawg dua 100K cycles | Zoo rau qhov txwv-tsim khoom nrog cov ntaub ntawv tsis-abrasive | ± 0.02 hli | Poob nyob rau hauv tus nqi qis rau nruab nrab | 10-15 hnub |

Chav Kawm 103 | Nruab nrab

| Tsawg dua 500K cycles | Rau qis rau nruab nrab-tsim qhov chaw | ± 0.02 hli | Poob nyob rau hauv cov nqi sib txawv | 10-15 hnub |

Chav Kawm 102 | Nruab nrab mus rau siab | Tsawg dua 1M | Zoo rau qhov chaw nrog cov ntaub ntawv abrasive thiab / lossis nruj kam rau ua | ± 0.02 hli | Tus nqi ncaj ncees thiab ua nrog cov ntaub ntawv zoo | 10-15 hnub |

Chav Kawm 101 | Siab heev | Tshaj 1M cycles | Kev tsim khoom siab heev thiab lub sijhawm voj voog ceev | ± 0.02 hli | Tus nqi siab tshaj thiab ua nrog tsuas yog cov ntaub ntawv zoo tshaj plaws | 10-18 hnub |