CNC Tshuab dhos vs CNC tig Center: Daim ntawv thov sib txawv

Lub Computer Numerical Control (CNC) tshuab tau hloov kho kev lag luam kev lag luam, muab cov khoom lag luam meej thiab ua tau zoo ntawm ntau yam khoom. Ob hom kev siv ntau tshaj plaws ntawm CNC tshuab yog tshuab dhos thiab tig chaw. Txawm hais tias ob qho tib si yog tsim los rau machining cylindrical qhov chaw, lawv muaj lawv qhov sib txawv ntawm daim ntawv thov.

CNC tshuab dhos yog cov cuab yeej siv tshuab uas tig lub tshuab ua haujlwm ntawm nws cov axis los ua haujlwm xws li txiav, drilling, knurling, thiab xuab zeb. Ntawm qhov tod tes, CNC tig qhov chaw yog qhov kev tshaj lij ntawm lub tshuab dhos nrog cov yam ntxwv ntxiv xws li milling peev xwm, cov cuab yeej nyob, thiab cov spindles thib ob.

Hauv tsab xov xwm no, peb yuav tham txog qhov sib txawv ntawm CNC tshuab dhos thiab CNC tig qhov chaw nyob rau hauv cov nqe lus ntawm daim ntawv thov, los pab koj nkag siab tias lub tshuab twg yog qhov zoo tshaj plaws rau koj cov kev xav tau tshwj xeeb.

CNC tshuab dhos yog dab tsi?

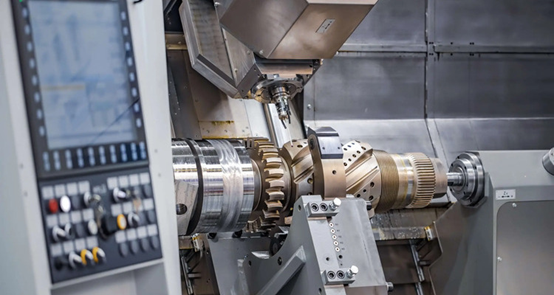

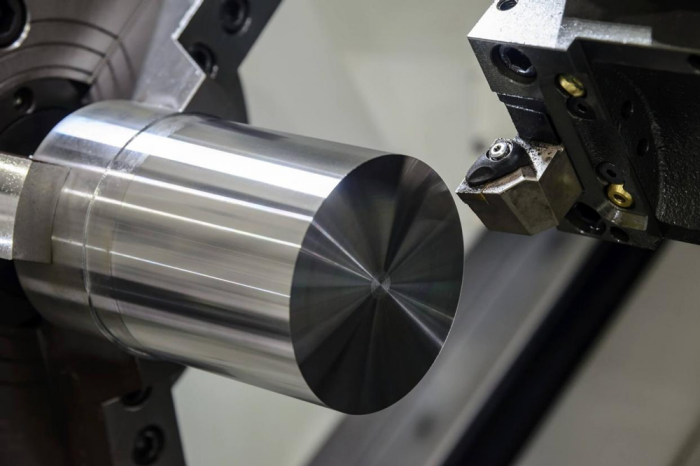

ACNC tshuab dhos yog cov cuab yeej siv tshuab uas tig lub workpiece ntawm nws cov axis los ua ntau yam haujlwm xws li txiav, drilling, knurling, thiab xuab zeb. Nws siv computer tswj los txhais cov lus qhia programmed rau hauv cov lus txib txav mus rau lub tshuab. Lub tshuab dhos muaj ob qhov tseem ceeb - lub taub hau thiab lub carriage. Lub headstock muaj lub ntsiab spindle uas tuav thiab tig lub workpiece, thaum lub carriage txav raws qhov ntev ntawm lub txaj los tswj cov cuab yeej txiav.

CNC lathes feem ntau yog siv rau machining cylindrical los yog conical zoo li tus Cheebtsam nrog siab precision thiab raug. Lawv kuj tseem siv tau rau kev tig ntsej muag, grooving, threading, thiab tho txawv ua haujlwm. Nrog rau lawv lub peev xwm los rov ua cov txheej txheem txiav ntau zaus, cov tshuab no yog qhov zoo tagnrho rau cov khoom ntim ntau ntawm cov khoom yooj yim.

CNC tshuab dhos muaj nyob rau hauv ntau qhov ntau thiab tsawg, xws li los ntawm cov qauv duab me me mus rau cov tshuab loj loj uas muaj peev xwm tuav cov haujlwm hnyav. Lawv feem ntau siv rau hauv tsheb, aerospace, thiab kev kho mob kev lag luam rau kev tsim khoom xws li shafts, pistons, thiab li qub.

Dab tsi yog CNC Turning Center?

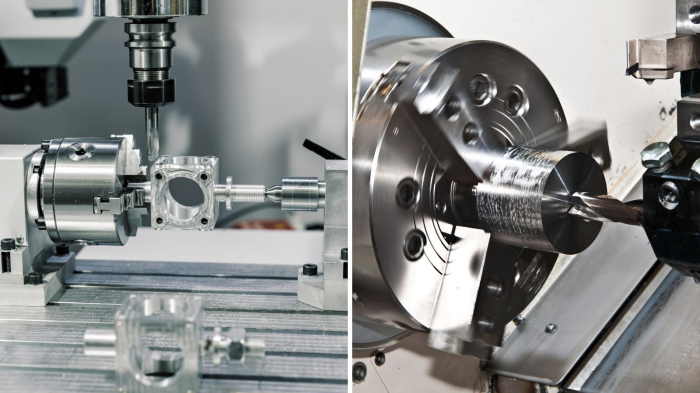

ACNC tig center yog ib tug advanced version ntawm lub tshuab dhos nrog ntxiv nta xws li milling muaj peev xwm, nyob tooling, thiab thib ob spindles. Nws muab cov kev ua haujlwm ntawm lub tshuab dhos thiab lub tshuab machining rau hauv ib lub tshuab, muab kev yooj yim dua thiab ua haujlwm zoo hauv kev tsim khoom.

Lub chaw xa khoom muaj qhov tseem ceeb spindle rau tig lub workpiece thiab ib tug thib ob spindle rau kev ua hauj lwm xws li milling, drilling, tapping, thiab off-center drilling. Qhov no tshem tawm qhov xav tau los hloov cov khoom ua haujlwm ntawm cov tshuab sib txawv, txuag lub sijhawm thiab txo qhov yuam kev.

CNC xa cov chaw yog feem ntau siv rau kev ua haujlwm nyuaj thiab ntau txoj haujlwm machining. Lawv tuaj yeem tsim cov duab sib txawv thiab cov yam ntxwv ntawm ob qhov kawg ntawm cov khoom ib txhij, ua rau lawv zoo tagnrho rau kev tsim cov khoom xws li lub zog, shafts nrog keyways lossis splines, thiab cov khoom siv kho mob nyuaj.

Ntxiv nrog rau lawv cov peev txheej siab, cov chaw xa khoom kuj tseem muaj lub sijhawm voj voog nrawm dua thiab siab dua piv rau CNC lathes. Lawv tau siv dav hauv kev lag luam xws li aerospace, kev tiv thaiv, thiab roj thiab roj rau lawv lub peev xwm los tsim cov khoom nyuaj nrog nruj kam rau ua.

Main Defferences ntawm CNC tshuab dhos thiab CNC tig Center

MuajNtau qhov sib txawv tseem ceeb ntawm CNC tshuab dhos thiab CNC tigcenter, uas ua rau lawv haum rau kev siv sib txawv.

Tsim

Kev tsim ntawm CNC tshuab dhos thiab CNC tig qhov chaw sib txawv heev, cuam tshuam rau lawv cov kev npaj siv thiab peev xwm. CNC tshuab dhos feem ntau yooj yim hauv kev tsim thiab feem ntau tsom rau kev ua haujlwm tig qhov chaw ua haujlwm tig thaum lub cuab yeej txiav tseem nyob ruaj khov. Nws suav nrog lub ntsiab spindle, headstock, thiab ib qho yooj yim carriage system los pab txhawb kev txav mus los.

Ntawm qhov tod tes, CNC tig qhov chaw yog ntau txoj hauv kev tsim thiab sib koom ua ke ntau yam kev ua haujlwm dhau ntawm kev tig. Nws suav nrog cov spindles ntxiv, cov cuab yeej nyob, thiab feem ntau muaj qhov Y-axis, ua kom nws ua haujlwm milling, drilling, thiab tapping cov haujlwm hauv tib lub teeb. Qhov no multi-functional tsim tso cai rau lub chaw tig los lis ntau intricate thiab multifaceted machining hauj lwm yam tsis tas yuav hloov lub workpiece mus rau ib tug txawv tshuab.

Cov qauv tsim sib txawv no ua rau CNC lathes zoo tagnrho rau kev ua haujlwm ncaj nraim, ntim ntau lawm thaum CNC tig cov chaw zoo dua rau kev ua haujlwm nyuaj, ntau txheej txheem tsim khoom.

Kev ua haujlwm

Lwm qhov sib txawv tseem ceeb ntawm CNC tshuab dhos thiab CNC tig qhov chaw yog ntau yam haujlwm uas lawv tuaj yeem ua tau. Raws li tau hais ua ntej, lub tshuab dhos feem ntau tsom rau kev ua haujlwm tig xws li tig ntsej muag, grooving, drilling, threading, thiab tho txawv. Cov tshuab no zoo tagnrho rau kev tsim cov cylindrical los yog conical yooj yim nrog kev ua haujlwm siab.

Lub caij no, lub chaw xa khoom muaj ntau qhov kev sib tw nrog nws lub peev xwm los tswj ntau yam txheej txheem ib txhij. Nws tuaj yeem ua ntau yam kev ua haujlwm milling xws li lub ntsej muag milling, kawg milling, thiab drilling siv cov cuab yeej nyob thaum lub hauv paus spindle tig lub workpiece. Qhov kev muaj peev xwm siab tshaj no tso cai rau ntau qhov geometry nyuaj kom ua haujlwm tau zoo hauv ib qho teeb tsa.

Thaum ob lub tshuab sib koom ua ke qee qhov kev ua haujlwm yooj yim xws li linear thiab rotational txav, lawv cov haujlwm ua haujlwm sib cais thiab ua rau ib qho haum rau qee yam kev siv dua li lwm qhov.

Yooj yim

Flexibility yog lwm qhov sib txawv tseem ceeb ntawm CNC tshuab dhos thiab CNC tig qhov chaw. Lub tshuab dhos yog tsim los tswj cov khoom ntim siab ntawm cov khoom siv yooj yim nrog kev hloov me ntsis hauv kev tsim. Nws tuaj yeem ua tau zoo tsim ntau qhov chaw zoo ib yam, ua rau nws zoo tagnrho rau kev tsim khoom loj.

Ntawm qhov tod tes, atig center muab kev hloov pauv ntau dua vim nws tuaj yeem ua raws li ntau yam qauv thiab cov ntaub ntawv yam tsis tas yuav tsum tau rov kho dua lossis hloov pauv. Nws muaj peev xwm ua haujlwm ntau yam ua rau nws los daws qhov nyuaj nrog cov yam ntxwv sib txawv thiab cov duab geometry hauv ib qho kev teeb tsa sai, txo cov sij hawm tsim khoom thiab cov nqi.

Qhov yooj yim muab los ntawm lub chaw tig ua rau nws tsim nyog rau qhov qis mus rau nruab nrab ntim ntawm cov khoom siv, tshwj xeeb tshaj yog nyob rau hauv kev lag luam xws li aerospace thiab kev kho mob qhov twg cov qauv tsim tau hloov tas li.

nyuaj

Nyob rau hauv cov nqe lus ntawm complexity, ib tug CNC tig qhov chaw yog undoubtedly ntau tshaj li ib tug kws dhos. Nws tsim muaj ntau yam spindles, nyob twj ywm, thiab Y-axis, ua rau nws muaj peev xwm tuav ntau yam haujlwm ib zaug. Qhov no nce nws tag nrho complexity tab sis kuj muab ntau dua versatility thiab efficiency nyob rau hauv ntau lawm.

Lub tshuab dhos, ntawm qhov tod tes, muaj qhov tsim qauv yooj yim nrog tsawg dua qhov txav thiab ua haujlwm. Qhov no ua rau nws yooj yim rau kev khiav lag luam thiab tswj tab sis txwv nws cov peev xwm piv rau lub chaw tig.

Raws li qhov yuav tsum tau ua ntawm cov txheej txheem ntau lawm, ob lub tshuab yuav nyiam dua. Rau cov khoom siv yooj yim nrog kev ua haujlwm tsawg, lub tshuab dhos yuav txaus. Txawm li cas los xij, rau ntau qhov chaw uas xav tau ntau yam txheej txheem, lub chaw xa khoom muaj peev xwm tsim nyog.

Ntau lawm ntim

Ib qhov sib txawv kawg ntawm CNC tshuab dhos thiab CNC tig qhov chaw yog lawv cov ntim ntim ntau lawm. Raws li tau hais ua ntej lawm, tshuab dhos feem ntau yog siv rau cov khoom ntim ntau ntawm cov khoom sib xws. Lawv cov qauv tsim yooj yim tso cai rau kev tsim khoom sai thiab lub sijhawm voj voog, ua rau lawv zoo tagnrho rau kev tsim khoom loj.

Ntawm qhov tod tes,tig centers yog zoo dua haum rau qhov tsawg mus rau nruab nrab ntim ntau lawm vim lawv cov peev txheej siab heev thiab muaj peev xwm los lis ntau yam qauv thiab cov khoom siv tau zoo. Lawv kuj muab sijhawm teem sijhawm luv dua piv rau cov chaw ua haujlwm ib txwm siv, ua rau lawv tsim nyog rau cov khoom me me nrog kev hloov pauv ntau zaus.

Yog li cov no yog qhov sib txawv tseem ceeb ntawm CNC tshuab dhos thiab CNC tig chaw. Txawm hais tias lawv yuav zoo sib xws thaum xub thawj siab ib muag, lawv cov qauv tsim, kev ua haujlwm, hloov tau yooj yim, tsis yooj yim, thiab cov ntim ntim ntau lawm muab lawv sib nrug thiab ua rau lawv zoo dua rau kev tsim khoom sib txawv. Kev nkag siab txog qhov sib txawv no tuaj yeem pab cov tuam txhab xaiv lub tshuab tsim nyog tshaj plaws kom tau raws li lawv cov kev xav tau tshwj xeeb thiab txhim kho lawv cov txheej txheem ntau lawm.

Yuav ua li cas xaiv ntawm CNC tshuab dhos thiab CNC tig Center

Thaum txiav txim siabnruab nrab ntawm CNC tshuab dhos thiab CNC tig qhov chaw , ob peb yam yuav tsum tau xav txog. Ua ntej, hom ntawm ib feem lossis cov khoom tsim tawm ua lub luag haujlwm tseem ceeb. Rau qhov yooj yim cylindrical lossis conical qhov chaw nrog cov ntim ntau lawm, lub tshuab dhos yuav yog qhov kev xaiv zoo tshaj plaws vim nws qhov ua tau zoo thiab tus nqi qis.

Ntawm qhov tod tes, rau ntau qhov chaw uas yuav tsum tau muaj ntau yam txheej txheem nrog cov khoom ntim qis mus rau nruab nrab, lub chaw tig yuav muab ntau dua thiab ntau yam.

Cov peev nyiaj yog lwm qhov tseem ceeb thaum xaiv ntawm cov tshuab no. Cov tshuab dhos feem ntau tsis tshua kim tshaj qhov chaw tig vim lawv cov qauv tsim yooj yim thiab tsawg dua functionality. Yog li ntawd, yog tias kev txwv nyiaj txiag yog ib qho teeb meem, lub tshuab dhos yuav yog qhov kev xaiv ntau dua.

Tsis tas li ntawd, nws yog ib qho tseem ceeb uas yuav tau xav txog qhov chaw muaj nyob hauv qhov chaw tsim khoom. Cov chaw xa khoom xav tau ntau qhov chaw hauv pem teb vim lawv qhov loj dua thiab cov khoom siv ntxiv xws li cov cuab yeej nyob thiab ntau cov spindles. Hauv kev sib piv, tshuab dhos me me thiab siv qhov chaw tsawg dua.

Thaum kawg, cov tuam txhab lag luam yuav tsum ua tib zoo ntsuas lawv cov kev xav tau tshwj xeeb thiab ntsuas lawv tawm tsam cov peev txheej thiab kev txwv ntawm txhua lub tshuab ua ntej txiav txim siab. Kev sab laj nrog cov kws tshaj lij thiab ua cov kev tshawb fawb zoo kuj tseem tuaj yeem pab xaiv lub tshuab tsim nyog tshaj plaws rau kev ua haujlwm zoo thiab muaj txiaj ntsig.

Puas yog kev sib xyaw ntawm ob lub tshuab muaj?

Yog lawm,cov tshuab ua ke uas suav nrog ob lub tshuab dhos thiab tig qhov chaw muaj peev xwm muaj nyob. Cov tshuab hybrid no muab qhov zoo tshaj plaws ntawm ob lub ntiaj teb, nrog lub peev xwm los ua ntau txoj haujlwm tig thaum tseem muaj peev xwm milling thiab drilling.

Cov qauv tsim hybrid tso cai rau kev ua kom yooj yim dua thiab ua haujlwm tau zoo hauv kev tsim khoom vim nws tshem tawm qhov xav tau rau ntau qhov kev teeb tsa thiab txo lub sijhawm voj voog. Nws kuj txuag tau qhov chaw ntawm cov khoom hauv pem teb los ntawm kev sib txuas ob lub tshuab ua ib qho.

Txawm li cas los xij, cov tshuab ua ke no yuav tsis haum rau txhua hom kev tsim khoom vim lawv feem ntau muaj kev txwv ntawm qhov loj thiab qhov nyuaj piv rau cov tshuab dhos ua ke lossis cov chaw tig.

Cov neeg tsim khoom yuav tsum ua tib zoo tshuaj xyuas lawv cov kev xav tau tshwj xeeb ua ntej nqis peev hauv lub tshuab hybrid kom ntseeg tau tias nws tuaj yeem ua tiav lawv cov kev xav tau. Lawv kuj yuav tsum xav txog cov peev txheej tu thiab kev ua haujlwm ntawm lub tshuab ua ke piv nrog cov tshuab cais rau txhua qhov haujlwm.

Tsis tas li ntawd, raws li thev naus laus zis txuas ntxiv mus, cov tshuab hybrid tau dhau los ua neeg ntse dua thiab muaj peev xwm los tuav cov haujlwm nyuaj ntxiv. Yog li ntawd, nws yog ib qho tseem ceeb kom nyob twj ywm tshiab ntawm qhov kev tsim kho tshiab hauv cheeb tsam no los txiav txim siab seb lub tshuab ua ke yuav yog qhov tsim nyog peev rau koj cov txheej txheem tsim khoom.

Qhov yuam kev kom zam thaum xaiv ntawm CNC tshuab dhos thiab CNC tig Center

Thaum txiav txim siab ntawm CNC tshuab dhos thiab CNC tig chaw, muaj qee qhov yuam kev uas cov tuam txhab yuav tsum zam. Nov yog qee qhov ntawm lawv:

- Xaiv raws tus nqi ib leeg : Txawm hais tias pob nyiaj siv yog qhov tseem ceeb heev, nws yuav tsum tsis yog qhov tseem ceeb ntawm kev txiav txim siab. Lub tshuab pheej yig dua tuaj yeem ua rau raug nqi ntau dua ntawm kev saib xyuas thiab kev ua haujlwm yog tias nws tsis tuaj yeem ua raws li qhov yuav tsum tau ua.

- Tsis saib xyuas los ntsuas cov kev xav tau ntau lawm : Nws yog ib qho tseem ceeb kom ua tib zoo ntsuam xyuas cov khoom tshwj xeeb uas tau tsim thiab lawv cov haujlwm yuav tsum tau ua ua ntej xaiv lub tshuab. Kev ua tsis tiav tuaj yeem ua rau xaiv lub tshuab tsis zoo uas tsis ua raws li txhua qhov kev xav tau ntau lawm.

- Tsis xav txog kev loj hlob yav tom ntej : Thaum nqis peev hauv lub tshuab CNC, cov tuam txhab lag luam yuav tsum xav txog lawv cov phiaj xwm kev loj hlob yav tom ntej. Lawv puas yuav xav tau lub tshuab loj lossis ntau dua hauv kab? Qhov no yuav cawm tau lawv los ntawm kev hloov lossis hloov kho lawv cov cuab yeej sai dua li qhov xav tau.

- Tsis quav ntsej cov nqi kho thiab kev ua haujlwm : Raws li tau hais ua ntej, tus nqi pib ntawm lub tshuab yuav tsum tsis yog tus nqi nkaus xwb. Cov neeg tsim khoom kuj tseem yuav tsum tau ua qhov tseem ceeb hauv kev saib xyuas thiab cov nqi ua haujlwm los txiav txim siab tag nrho cov nqi-zoo ntawm lub tshuab.

Los ntawm kev zam cov kev ua yuam kev no, cov tuam txhab lag luam tuaj yeem ntsuas lawv cov kev xaiv zoo dua thiab xaiv lub tshuab tsim nyog tshaj plaws rau lawv cov kev xav tau ntau lawm, ua rau muaj txiaj ntsig zoo thiab muaj txiaj ntsig.

Hu rau Breton Precision rau koj CNC tig thiab lwm yam kev tsim khoom xav tau

Breton Precision yog koj qhov chaw nres tsheb rau tag nrho kojCNC tshuab dhos thiab CNC tig qhov chaw xav tau . Nrog peb cov thev naus laus zis siab heev thiab cov kws tshaj lij, peb tuaj yeem muab cov khoom zoo tshaj plaws rau koj cov haujlwm tshwj xeeb. Peb muab ntau yam ntawmcov kev pabcuam suav nrogon-hu CNC tig, ceev txhuas lub sij hawm, thiab 24/7 engineering txhawb kom ntseeg tau siab tshaj plaws ntawm cov neeg siv khoom txaus siab.

Peb lub tuam txhab tau cog lus tias yuav xa cov khoom zoo tshaj plaws nrog precision thiab efficiency. Peb muaj kev tswj hwm nruj nruj nyob rau hauv qhov chaw kom ntseeg tau tias tag nrho peb cov khoom ua tau raws li cov qauv xav tau thiab tsis muaj qhov tsis xws luag.

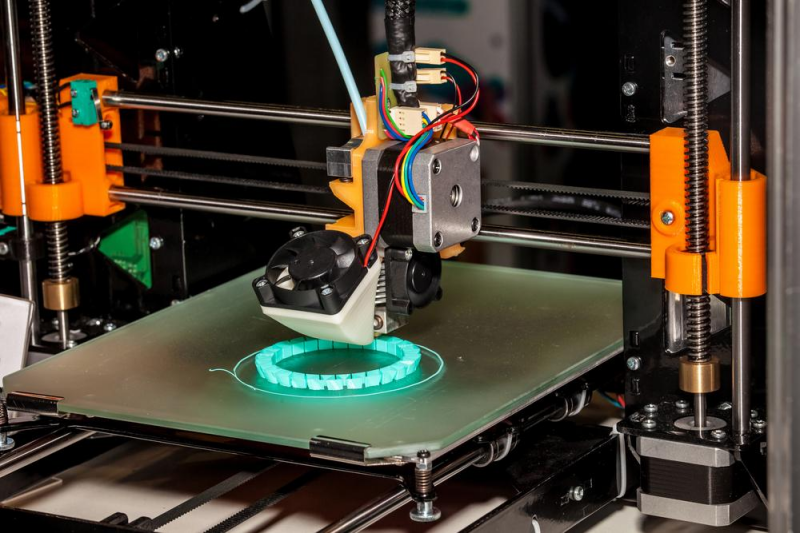

Nrog rau peb cov khoom siv hluav taws xob thiab cov khoom siv niaj hnub, peb tshwj xeeb hauvCNC machining,yas txhaj tshuaj molding,sheet hlau fabrication,nqus casting, thiab3D luam ntawv . Peb pab neeg ntawm cov kws tshaj lij tuaj yeem tswj cov haujlwm xws li kev tsim cov qauv mus rau kev tsim khoom loj nrog yooj yim. Peb kuj muabkev sib tw nqithiab lub sijhawm ua haujlwm ceev, xyuas kom koj cov haujlwm ua tiav raws sijhawm thiab raug nqi zoo.

NtawmBreton Precision , peb nkag siab qhov tseem ceeb ntawm precision thiab raug hauv kev tsim khoom. Yog vim li cas peb siv zog ua kom ua tau raws li qhov siab ntawm ± 0.005 "rau milled hlau, ua tau raws li ISO cov qauv rau cov yas thiab hlau.

Tiv tauj peb ntawmyog info@breton-precision.com los yog hu rau peb ntawm 0086 0755-23286835 rau tag nrho koj CNC tig thiab lwm yam kev tsim khoom xav tau. Peb pab pawg kws tshaj lij muaj nyob rau 24/7 los muab cov kev daws teeb meem zoo tshaj plaws rau koj los tsim, xaiv cov ntaub ntawv, thiab tswj cov sij hawm txhuas. Cia peb pab kojnqa koj tej yaam numrau lub neej nrog peb cov kev pabcuam zoo CNC tig.

FAQs

Dab tsi yog qhov txawv ntawm CNC tshuab dhos tshuab thiab CNC tig qhov chaw?

CNC tshuab dhos yog cov cuab yeej tshwj xeeb uas tsim los rau kev txiav, xuab zeb, knurling, thiab cov ntaub ntawv drilling. Lub chaw CNC tig, ntawm qhov tod tes, suav nrog cov peev txheej ntxiv xws li milling thiab tapping, ua rau nws muaj ntau yam kev xaiv rau cov txheej txheem machining nyuaj.

Yuav ua li cas ntsug tig qhov chaw sib piv rau cov tsoos lathes nyob rau hauv cov nqe lus ntawm machining peev xwm?

Vertical turning centers yog ib hom CNC tshuab dhos uas ua haujlwm nrog ntsug spindle orientation. Qhov kev teeb tsa no tshwj xeeb yog qhov zoo rau cov khoom hnyav, loj workpieces. Nyob rau hauv sib piv, ib txwm lathes feem ntau feature ib kab rov tav spindle thiab zoo dua haum rau tej yam yooj yim, me me.

Dab tsi yog txoj hauv kev ua CNC machining txheej txheem hauv cov chaw xa khoom txawv ntawm CNC tshuab dhos tshuab?

Cov txheej txheem CNC machining nyob rau hauv cov chaw xa khoom sib txawv ntawm CNC tshuab dhos tshuab hauv cov chaw xa khoom tuaj yeem ua tau ob qho tib si tig thiab milling ua haujlwm yam tsis muaj kev hloov pauv, uas txhim kho kev tsim khoom. CNC tshuab dhos tshuab, thaum siv tau zoo, feem ntau tsom rau kev ua haujlwm tig nkaus xwb.

Vim li cas cov chaw tsim khoom yuav xaiv lub tshuab dhos CNC hla CNC tig chaw rau qee yam kev siv?

Cov neeg tsim khoom tuaj yeem xaiv lub tshuab dhos CNC hla lub CNC tig qhov chaw rau cov ntawv thov uas xav tau kev ua haujlwm tig yam tsis tas yuav tsum tau milling lossis drilling txheej txheem ntxiv. CNC tshuab dhos feem ntau yog yooj yim dua thiab tsis tshua kim tshaj kab rov tav tig qhov chaw, ua rau lawv haum rau ncaj machining cov hauj lwm.

Xaus

Hauv kev xaus, kev txiav txim siab ntawm CNC tshuab dhos thiab CNC tig qhov chaw kawg yog nyob ntawm cov chaw tsim khoom tshwj xeeb cov kev xav tau ntau lawm. Hybrid cov cav tov tuaj yeem muab kev ua kom yooj yim dua thiab ua haujlwm tau zoo, tab sis lawv yuav tsis haum rau txhua hom kev tsim khoom. Nws yog ib qho tseem ceeb kom ua tib zoo soj ntsuam koj cov kev xav tau ntau lawm ua ntej nqis peev hauv ib lub tshuab.

Tsis tas li ntawd, nws yog ib qho tseem ceeb kom tsis txhob muaj kev ua yuam kev xws li xaiv ib leeg raws li tus nqi thiab tsis saib xyuas los txiav txim siab txog cov phiaj xwm kev loj hlob yav tom ntej.Breton Precisionmuab cov khoom zoo tshaj plawsCNC xa cov kev pabcuamthiab lwm yamkev daws teeb meem nrog cov nqi sib tw thiab lub sijhawm ua haujlwm ceev. Tiv tauj peb hnub no rau txhua yam koj xav tau kev tsim khoom!